OS-T: 2010 Design Concept for an Automotive Control Arm

In this tutorial you will use OptiStruct's topology optimization functionality to create a design concept for an automotive control arm required to meet performance specifications.

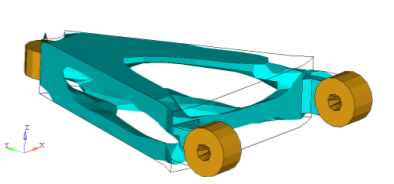

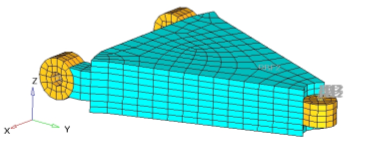

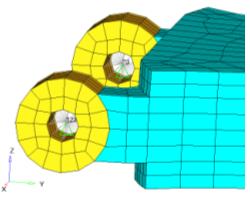

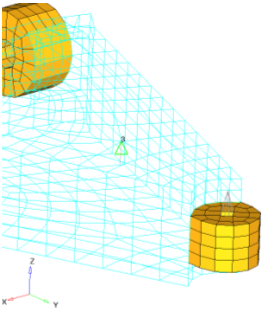

Figure 1. Finite Element Mesh Containing Designable (blue) and Non-Designable (yellow) Material

- Objective

- Minimize volume.

- Constraints

- SUBCASE 1. Resultant displacement of the point where loading is applied must be less than 0.05mm.

- Design Variables

- Element density (and corresponding stiffness of the element) of each element in the design space.

Launch HyperMesh and Set the OptiStruct User Profile

Open the Model

Set Up the Model

Create the Material

Create the Property

Assign a Material and Property to the nondesign Component

Apply Loads and Boundary Conditions

Create Load Collectors

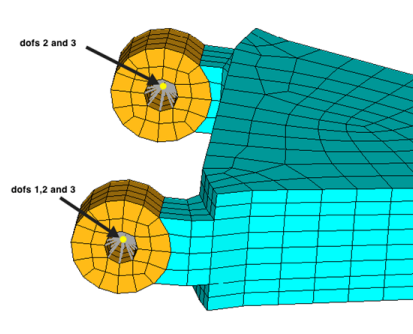

Apply Constraints

Apply Forces to the Brake, Corner and Pothole Loadcases

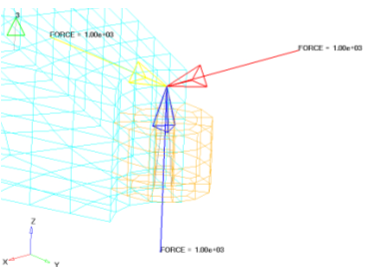

Figure 5. Forces Applied to the Brake, Corner and Pothole Loadcases. for better visualization of the forces, the design component is turned off using the Display panel

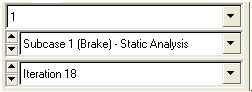

Create Load Steps

- In the Model Browser, right-click and select from the context menu.

- For Name, enter Brake.

- Set Analysis type to linear static.

-

Define SPC.

- For SPC, click .

- In the Select Loadcol dialog, select SPC and click OK.

-

Define LOAD.

- For LOAD, click .

- In the Select Loadcol dialog, select Brake and click OK.

-

Repeat the above steps to create load steps named Corner and Pothole.

- For the Corner load step, set SPC to SPC and LOAD to Corner.

- For the Pothole load step, set SPC to SPC and LOAD to Pothole.

Set Up the Optimization

Create Topology Design Variables

- From the Analysis page, click optimization.

- Click topology.

- Select the create subpanel.

- In the desvar= field, enter design_prop.

- Set type: to PSOLID.

- Using the props selector, select design_prop.

- Click create.

- Click return.

Create Optimization Responses

- From the Analysis page, click optimization.

- Click Responses.

-

Create the volume response, which defines the volume fraction of the design

space.

- In the responses= field, enter vol.

- Below response type, select volume.

- Set regional selection to total and no regionid.

- Click create.

-

Create the displacement response.

- Click return to go back to the Optimization panel.

Create Constraints on Displacement Responses

- Click the Dconstraints panel.

-

Create the first constraint.

- In the constraint= field, enter constr1.

- Check the box next to upper bound, then enter 0.05.

- Click response= and select disp1.

- Using the loadsteps selector, select Brake.

- Click create.

-

Create the second constraint.

- In the constraint= field, enter constr2.

- Check the box next to upper bound, then enter 0.02.

- Click response= and select disp1.

- Using the loadsteps selector, select Corner.

- Click create.

-

Create the third constraint.

- In the constraint= field, enter constr3.

- Check the box next to upper bound, then enter 0.05.

- Click response= and select disp1.

- Using the loadsteps selector, select Pothole.

- Click create.

- Click return to go back to the Optimization panel.

Define the Objective Function

- Click the objective panel.

- Verify that min is selected.

- Click response= and select vol.

- Click create.

- Click return twice to exit the Optimization panel.

Check the Optimization Problem

- Is the optimization problem set up correctly?

- Refer to the Optimization Problem Parameters section.

- Is the objective function set up correctly?

- Refer to the Problem Parameters section.

- Are the constraints set up correctly?

- Refer to the Optimization Problem Parameters section.

- What is the recommended amount of RAM for an In-Core solution?

- Refer to the Memory Estimation Information section.

- Is there enough disk space to run the optimization?

- Refer to the Disk Space Estimation Information section.

Run the Optimization

- carm_complete.res

- HyperMesh binary results file.

- carm_complete.HM.comp.cmf

- HyperMesh command file used to organize elements into components based on their density result values. This file is only used with OptiStruct topology optimization runs.

- carm_complete.out

- OptiStruct output file containing specific information on the file setup, the setup of the optimization problem, estimates for the amount of RAM and disk space required for the run, information for all optimization iterations, and compute time information. Review this file for warnings and errors that are flagged from processing the carm_complete.fem file.

- carm_complete.sh

- Shape file for the final iteration. It contains the material density, void size parameters and void orientation angle for each element in the analysis. This file may be used to restart a run.

- carm_complete.hgdata

- HyperGraph file containing data for the objective function, percent constraint violations, and constraint for each iteration.

- carm_complete.oss

- OSSmooth file with a default density threshold of 0.3. You may edit the parameters in the file to obtain the desired results.

- carm_complete.stat

- Contains information about the CPU time used for the complete run and also the break-up of the CPU time for reading the input deck, assembly, analysis, convergence, and so on.

- carm_complete.his_data

- The OptiStruct history file containing iteration number, objective function values and percent of constraint violation for each iteration.

- carm_complete.HM.ent.cmf

- HyperMesh command file used to organize elements into entity sets based on their density result values. This file is only used with OptiStruct topology optimization runs.

- carm_complete.html

- HTML report of the optimization, giving a summary of the problem formulation and the results from the final iteration.

View the Results

Element density results are output to the carm_complete_des.h3d file from OptiStruct for all iterations. In addition, Displacement and Stress results are output for each subcase for the first and last iterations by default into carm_complete_s#.h3d files, where # specifies the sub case ID.

to

move to the third page.

to

move to the third page. ).

). to open the

to open the  to open the Deformed panel.

to open the Deformed panel. (Start/Pause) to animate the model.

(Start/Pause) to animate the model.

to

stop the animation.

to

stop the animation. to

go back to the Design History page.

to

go back to the Design History page.