Springback Reference Part and Constraints

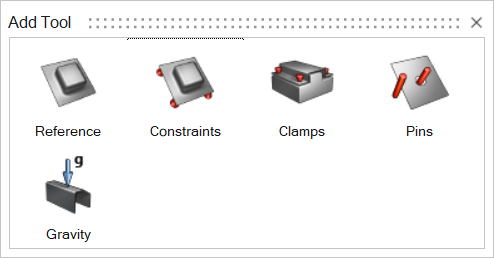

Use springback tools to define a reference part and constraints in a springback operation.

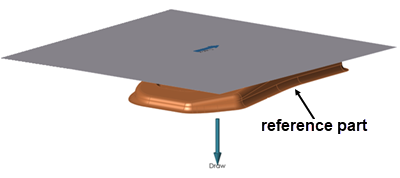

Define Reference Part

Define a reference part in your model for a springback operation.

The reference part helps to locate any defined constraints on the formed part shape. This is helpful when a multi stage forming process is required and the formed part shape before springback is no longer available.

Define Springback Constraints

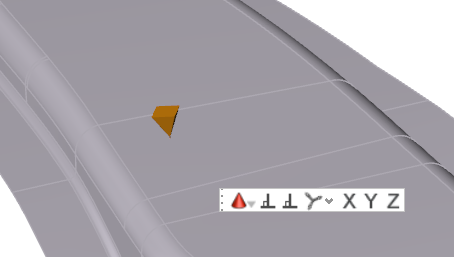

Define constraints to hold a part in its designated position during a springback operation.

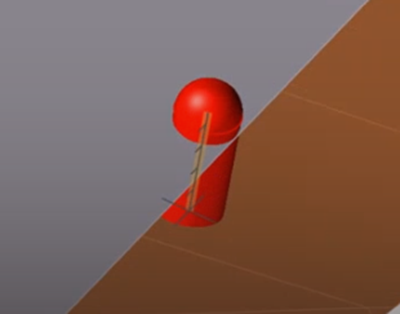

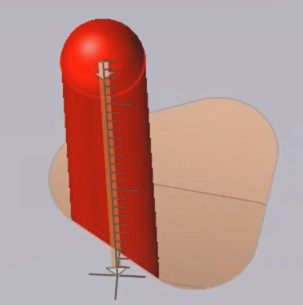

You can apply constraints to a single point on the model, to an edge, or a face.

You can define springback constraints only on a meshed blank or reference part that is either geometry or a mesh representation.

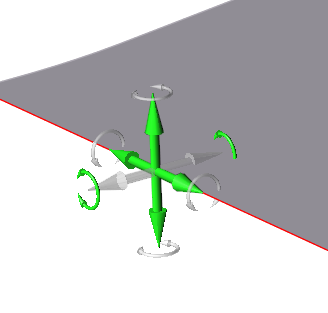

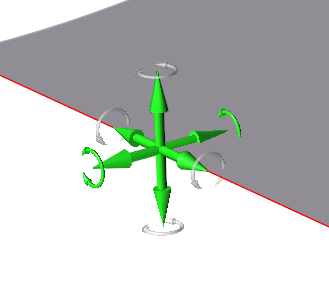

Translate or Rotate Constraints

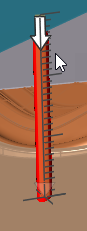

When you create a support, translation is locked in all directions by default; you can edit individual supports to allow translation in one or more directions.

Supports applied to a point, line, or face can translate in up to three

directions.

Supports applied to a point, line, or face can translate in up to three

directions.Apply a Constraint to a Cylindrical Hole

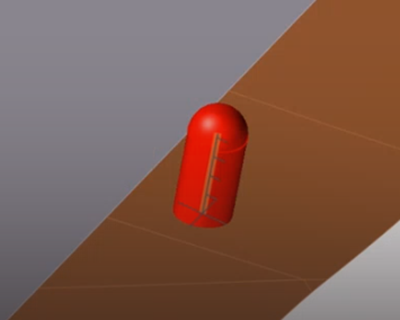

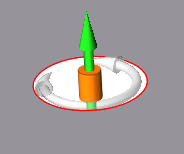

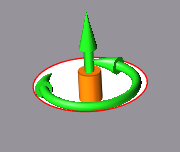

Constraints applied to a cylindrical hole are a special case, and have different properties from constraints applied to a point, edge, or face.

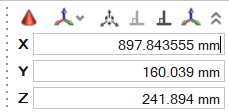

Microdialog Options

Double-click a constraint to enter editing mode, which opens the Support microdialog.

|

|

Translate or rotate the support using the Move tool. Use to place a support at a distance. |

|

|

Align the support normal (perpendicular) to the face. |

|

|

Align the support normal to the draw direction. |

|

|

Align the support to the global axes. |

Clamps

Add Clamps to your Springback operation.

Gravity

Add Gravity to a Springback Operation.

Add and Configure Pins

Add guide pins to your tool set to secure the blank between the top and bottom dies during a forming operation.

- In the guide bar, select Pin. If you have already left the context of the guide bar, click the existing Pin tool from the tool set of the forming operation.

- Repeat the tasks from Step 5 to configure the pin.

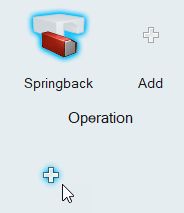

button below the springback operation.

button below the springback operation.

in the microdiolog, then enter values

for

in the microdiolog, then enter values

for

dropdown arrow, then select

dropdown arrow, then select

option appears. Click

option appears. Click

.

. .

. .

. .

. .

.