Refinement Zones for Commercial Heavy Trucks

This section will describe the commercial heavy truck best practice setup. Note that many of the logics and setup schemes are related to the passenger car setups. It is recommended to first read through the passenger vehicle section.

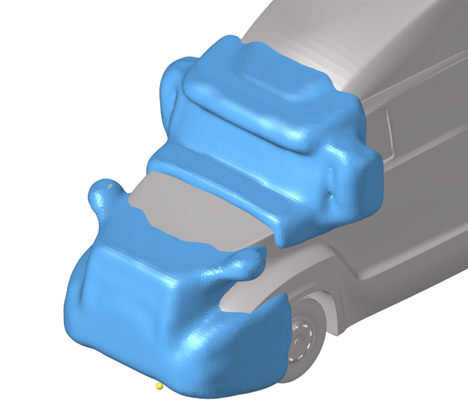

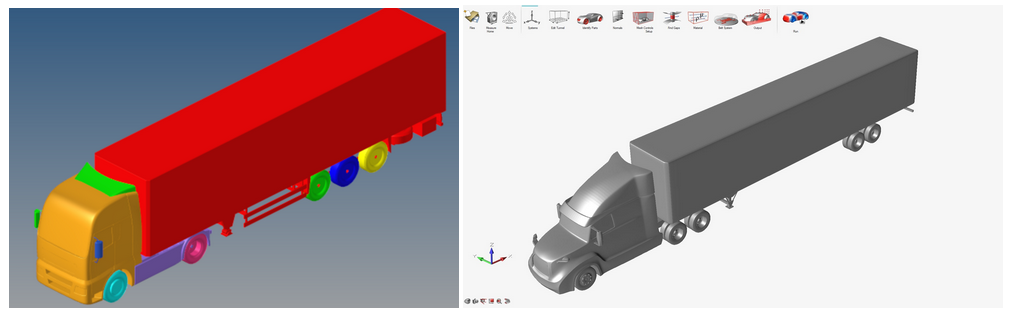

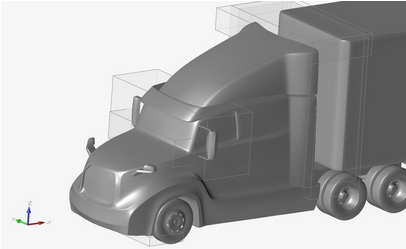

Figure 1. Example commercial class 8 trucks. Left cab-over (Source FAT), right long-nose (Altair demo truck)

Domain and resolution levels

- Refinement Level Vozel Size (mm)

-

- RL 0: 384 mm

- RL 1: 192 mm

- RL 2: 96 mm

- RL 3: 48 mm

- RL 4: 24 mm

- RL 5: 12 mm

- RL 6: 6 mm

- RL 7: 3 mm

- RL 8: 1.5 mm

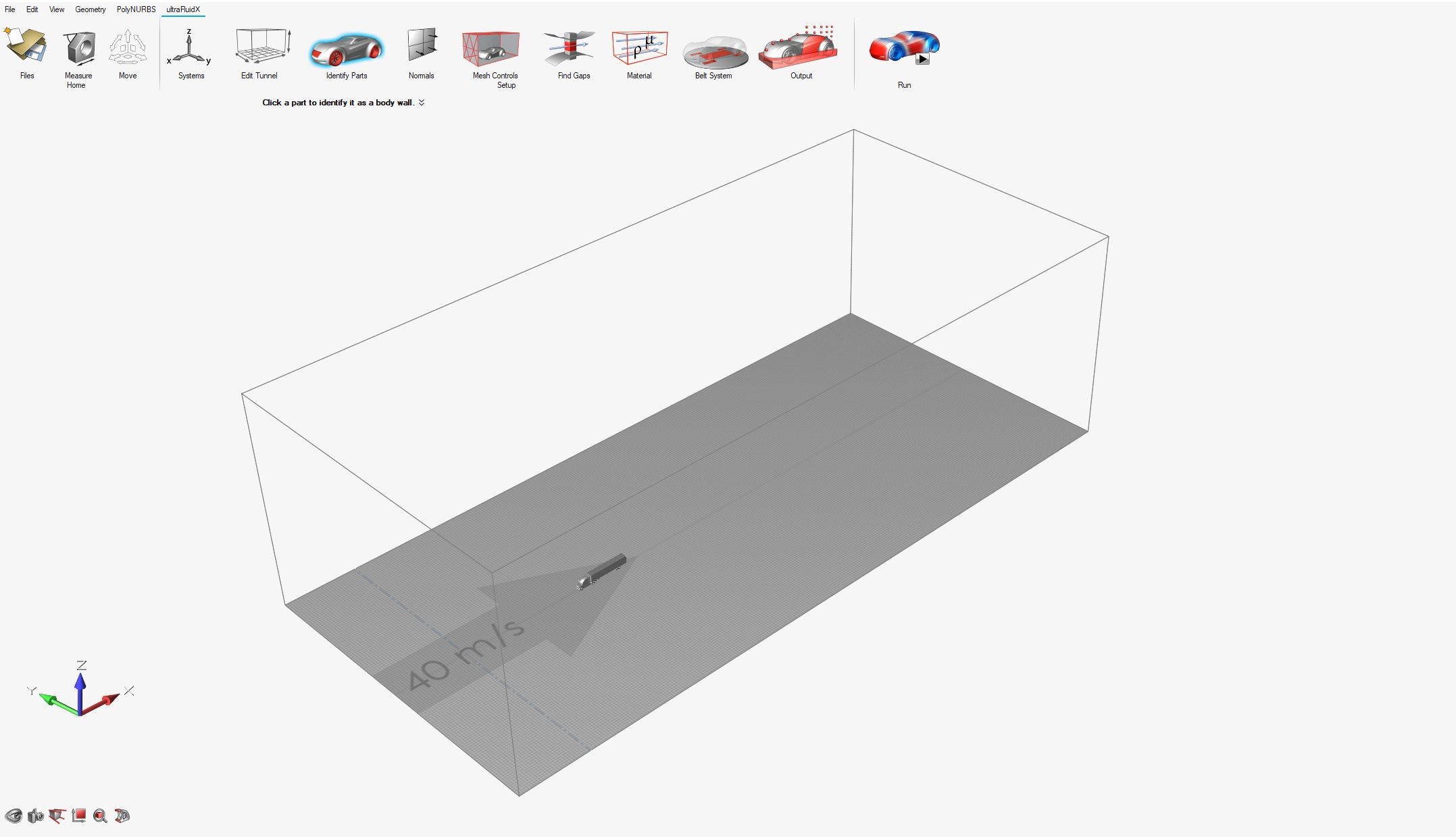

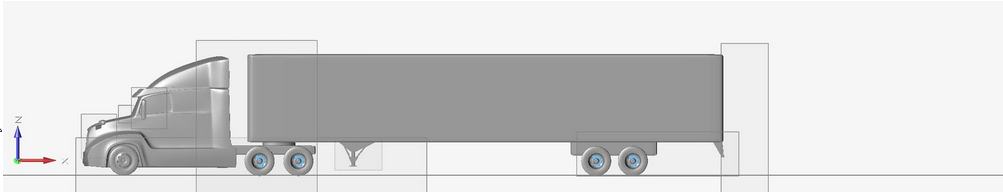

Figure 2. Domain in VWT for a truck

| Recommended domain size tractor-trailer combination in lengths | |

|---|---|

| +x | 2 |

| -x | 4 |

| +y | 1 (or 12 widths) |

| -y | 1 (or 12 widths) |

| +z | 1.5 (or 20 heights) |

VWT will create a default tunnel which is sized to provide a blockage ratio of 0.5% and is adequate for standard open road simulations.

Vehicle box refinement for outer regions (RL 1 though 3)

For commercial trucks, the general resolution strategy for the outer 3 refinement regions is similar, with a shift towards the rear of the tunnel to capture the wake structures. In summary as before, it is recommended that RL1 is at least:

- X: 3 vehicle lengths downstream, 1 vehicle length upstream of the vehicle

- Y: at least one vehicle width off to the sides

- Z: at least one vehicle height above the vehicle

RL2 and RL3 are scaled down from there. It is recommended that RL3 end one length behind the vehicle.

Figure 3. Side view of the domain, depicted the creation of RL2 in yellow. Truck and trailer indicated by the smaller RL zones

Major regions of resolution

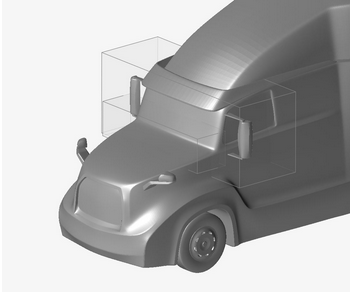

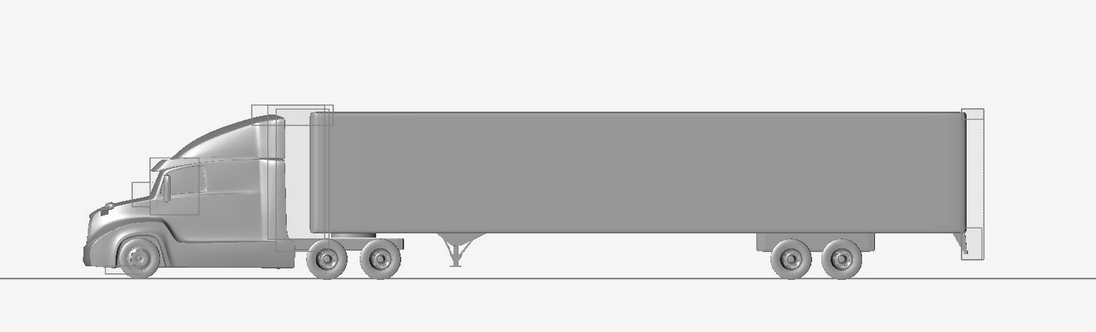

Figure 4. The inner resolution levels used below to describe best practices setup

Figure 5. Side view and top view of RL4 placement for trucks, covering engine bay, tractor, underbody and wake

Figure 6. RL5 placement example, covering cowl, mirrors engine bay, tractor underbody, landing gear, trailer wheels, near wake, interface gap

Figure 7. RL5 placement around main mirrors and cowl

Figure 8. RL6 regions, cooling pack, bumper shear layer, interface gap at high shear locations, separation shear layer at tail end of trailer

Figure 9. RL6 regions further detailing

Offset refinement overall

The trailer and the aero surfaces will in general have an RL6 offset of 4 cells (4x 6 mm). The engine bay and underbody in regions that do not directly touch the main underbody flow can be in RL5 if needed for voxel count reduction. Specific regions are selected for having RL7 and/or a larger number of RL6 offsets. These regions will be defined in the long-nose and cab-over sections of this chapter.

Refinement details for all trucks

The following refinement boxes or custom regions are recommended for all truck types. It is geometry dependent whether a box or a custom region is needed. Some regions have already been mentioned.

- Tractor-trailer interface gaps

- The shear layer in the tractor-trailer as well as inter-trailer gaps is

important and needs to be resolved in RL6 (6 mm). If the geometry is

axis aligned such that a box region suffices to capture the shear layer,

this is ok. Else a custom region can be created out of a simplified

shape, like a morphed shape.

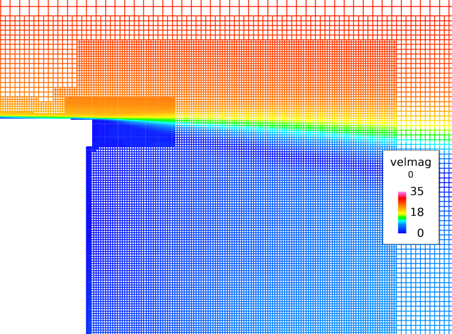

Figure 10. Regions in the interface gaps that need to be covered, in green - Trailer base

- The base of the trailer needs to be covered all around (top, sides,

bottom including bars) using refinement boxes in RL6. This should cover

the boundary layer and the separating shear layer over the edge for the

first 0.4m.

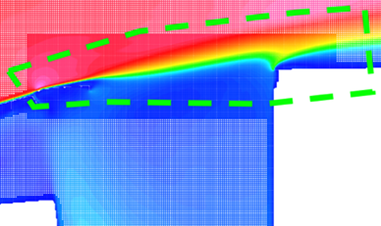

Figure 11. Resolution coverage at the base of the trailer, not the finest region around separation - Shear layers off the front bumper

- At the bottom of the front bumper, the flow typically separates, and the

shear layer is interacting with the underbody elements of the tractor.

This shear layer should be captured in RL6 using a custom refinement

zone. Any element that is impinging the main flow should have 8 x RL6

offset voxels as well for the first 2m underneath the tractor.

Figure 12. Custom zone for capturing the shear layer off the front bumper (in green), and offsets needed for impinging parts (example at green arrow) - Cooling pack flow

- The flow through the grill elements and past the cooling pack is important. Use either a box or custom refinement region to capture this flow at least in RL5, preferably RL6.

- Treatment of the wheels

- Commercial trucks typically have more closed rims compared to passenger vehicles. For that reason, an MRF setup is not needed, and a moving wall boundary condition suffices for the rims, axles, brakes and tires.

Considerations for long-nose trucks

Figure 13. Example long-nose truck using the Altair Truck

- Custom refinement regions

- It is recommended to create the following custom refinement regions:

Considerations for cab-over commercial trucks

Figure 17. Example cab-over truck (Source FAT)

- Air curtain

- Cab-over trucks typically can have a flow deflector around the front

corners to prevent soiling onto the side-glass and door handles, called

an air curtain.

Figure 18. Air curtains on cab-over trucks - Leading edge corner flows

- For cab-over trucks, the flow around the leading-edge corners is

important. It is suggested to isolate the parts over the full height and

set a part offset of 8 layers RL7 (3 mm) plus an offset of 8 layers of

RL6 (6 mm) on top of that.

Figure 19. Offset regions for leading edge corner flow on cab-over trucks (model source FAT)

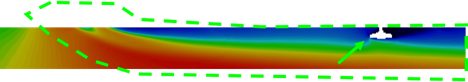

Yaw-angle notes

The current best practices for the previous truck sections are set for 0-degree yaw angle. However, for commercial truck applications, a yaw angle (for example, 5 or 10 degrees) can be an interesting case to investigate. The leeward side of the trucks will have a large wake, which would be filled in from the top/bottom of the trailer, from leeward edges of the tractor, and from cross-flow in the tractor-trailer gap.

Considerations for yaw setups:

- The leeward edges should have a shaped refinement zone to capture the separation (RL6).

- The wake on the leeward side should be adequately captured in RL5 and RL4. This can be achieved using combined loose wraps of 0 yaw until maximum yaw surfaces.

- The tractor trailer gaps should have at least RL5 in the whole interface to cover cross-flow.

Run-time of the simulation

A full tractor-trailer combination is typically a lot longer than a passenger vehicle. 8 flow passes is recommended to settle the flow, and another 8 for measurement of the required variables.

For example, for a 16m long combination, inflow 25 m/s, there are 25/16=1.6 flow passes per second. The recommended setting would be:

- Total simulation time 10s

- Start of averaging time 6s (measuring between 5s and 10s)

In conclusion: mesh setup for commercial trucks

For 0 yaw, the current best practice should generate a setup of around 220-320 million voxels, which would run for 10 seconds physical time in less than 1 day on Nvidia 8 x V100 GPUs.