Sensitivity

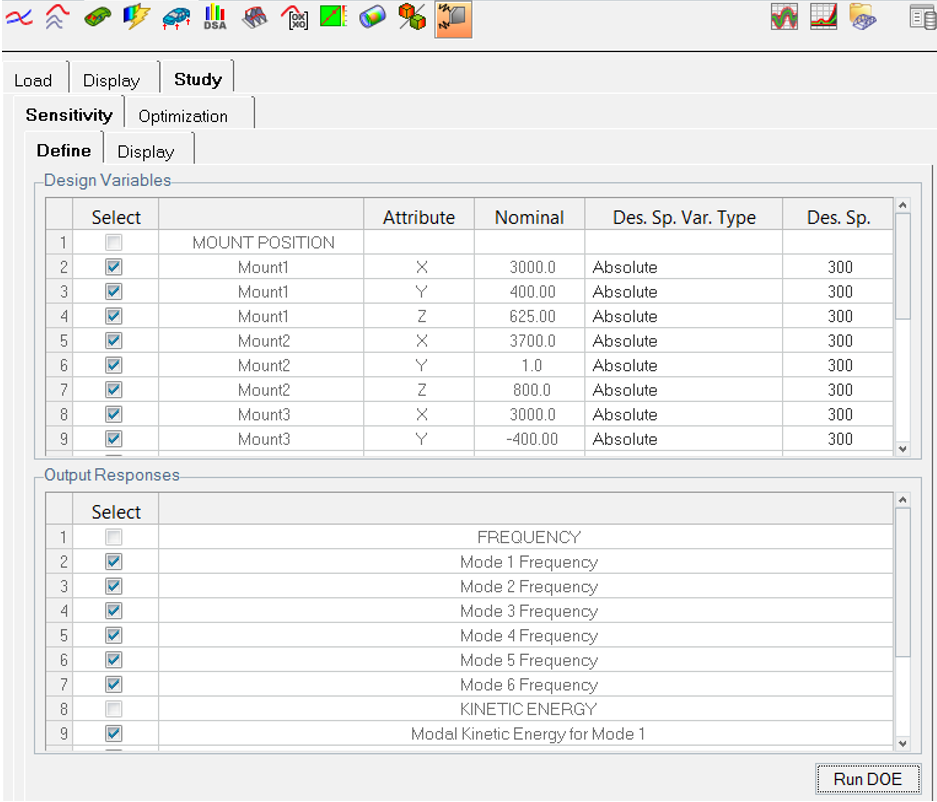

Define design variables and output responses to set up and execute design of experiments (DOE).

Figure 1. Mount Optimization Utility - Study Tab - Sensitivity sub-tab - Define

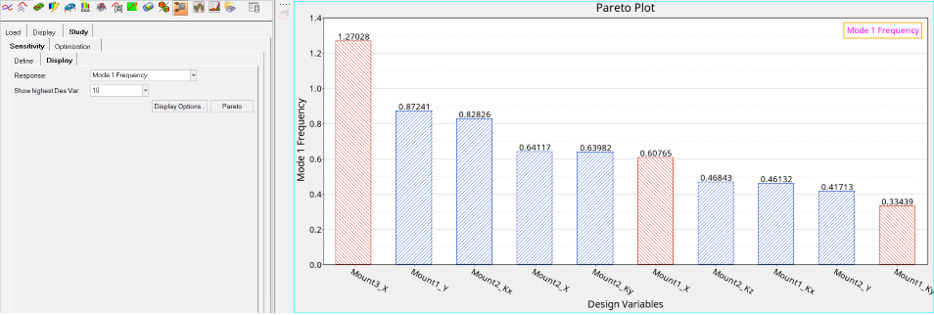

Pareto plots display sensitivity of variables to different output responses.

Figure 2. Mount Optimization Utility - Study Tab - Sensitivity sub-tab - Display