RD-E: 1703 Distorted

A steel box beam, fixed at one end and impacted at the other by an infinite mass. Results for distorted meshes are compared.

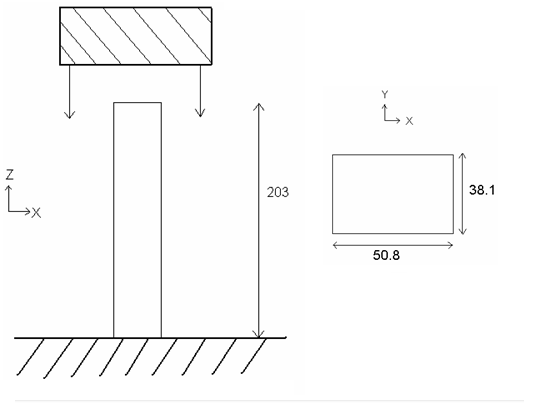

A steel box beam fixed at one end, is impacted at the other end by an infinite mass. The dimensions of the box beam are 203 mm x 50.8 mm x 38.1 mm, and its thickness is 0.914 mm. As symmetry is taken into account, only one quarter of the structure is modeled. Four kinds of mesh and three plasticity formulations are compared (global plasticity, five integration points and iterative plasticity).

Options and Keywords Used

- Q4 shells

- Interfaces (/INTER/TYPE7 and /INTER/TYPE11)

The structure's self-impact is modeled using a TYPE7 interface on the full structure. The interface main surface is defined using the complete model. The secondary nodes group is defined using the main surface.

On top of the beam, the possible edge-to-edge impacts are dealt with using a TYPE11 self-impacting interface. The edges use the main surface of the TYPE7 interface as the input surface.

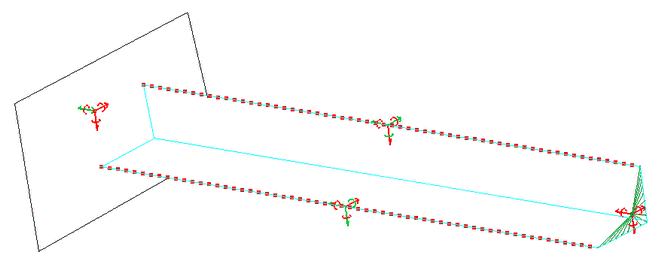

Figure 1. Boundary Conditions - Global plasticity, iterative plasticity, and variable thickness

- BT_TYPE1-3-4, QEPH, BATOZ, DKT18 and C0 formulation

- Boundary conditions (/BCS)

Take into account the symmetry, all nodes in the Y-Z plan are fixed in a Y translation and an X and Z rotation. One quarter of the structure is modeled.

- Rigid wall (/RWALL)

The impactor is modeled using a sliding rigid wall with a fixed velocity (13.3 m/s) in the Z-direction and fixed for other translations and rotations.

- Imposed velocity (/IMPVEL)

- Rigid body (/RBODY)

The lower (fixed) end is modeled using a rigid body connecting all lower nodes (Z = 0.0). The rigid body is completely fixed in translations and rotations.

Input Files

Model Description

Units: mm, ms, g, N, MPa

- Material Properties

- Value

- Initial density

- 7.8 x 10-3

- Young's modulus

- 210000

- Poisson ratio

- 0.3

- Yield stress

- 206

- Hardening parameter

- 450

- Hardening exponent

- 0.5

- Maximum stress

- 340

Figure 2. Problem Studied

Model Method

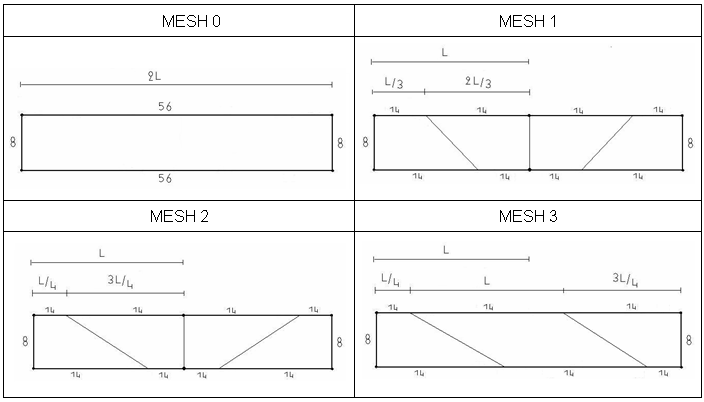

Four beams are modeled with different kinds of mesh, all having 56 elements in length and 8 in height. The layout of the elements is shown in Figure 3.

- Element formulation:

- BT_TYPE1

- BT_TYPE3

- QEPH

- BATOZ

- C0

- DKT18

- Plasticity:

- Global plasticity

- Progressive plasticity with five integration points

- Iterative plasticity with five integration points and variable thickness

Figure 3. Meshes

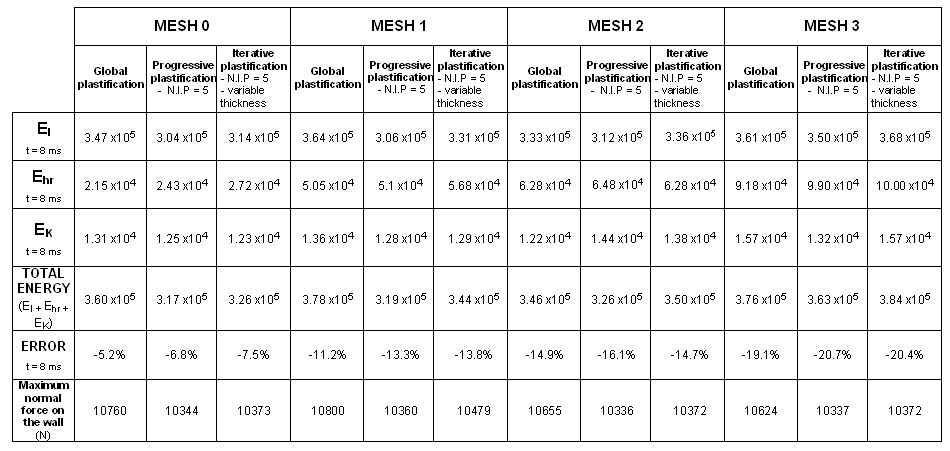

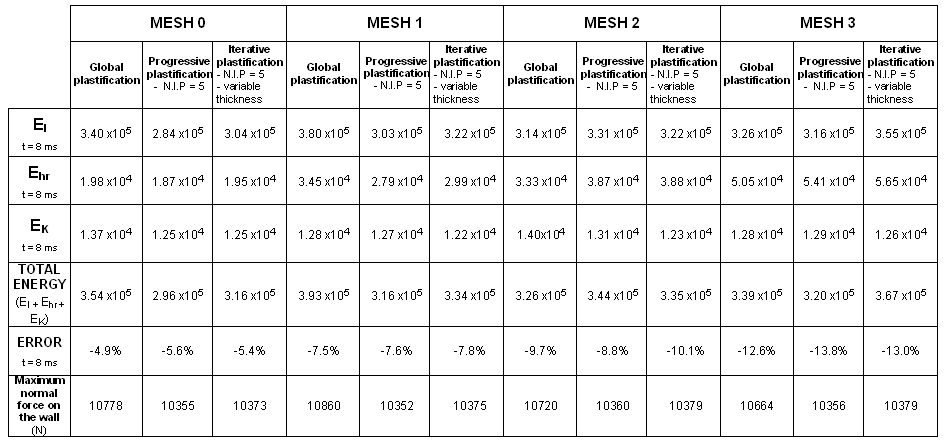

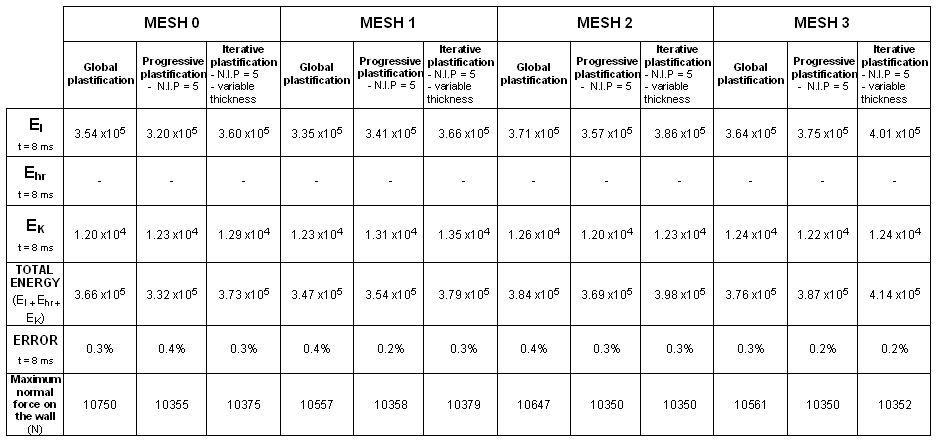

Results

- Role and influence of the mesh for a given type of element Formulation

- Shell element formulations for a given mesh.

- Plasticity options for a given mesh and element Formulation

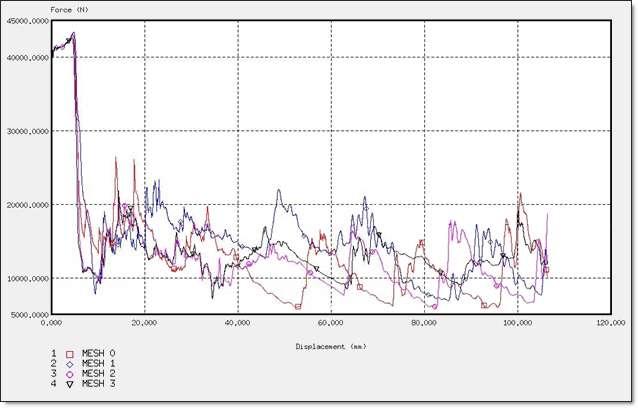

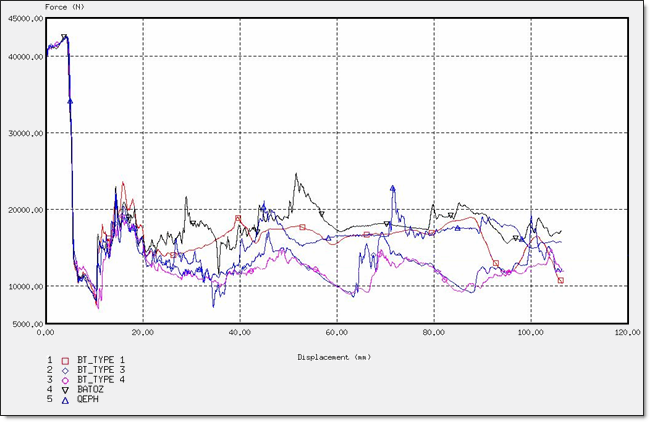

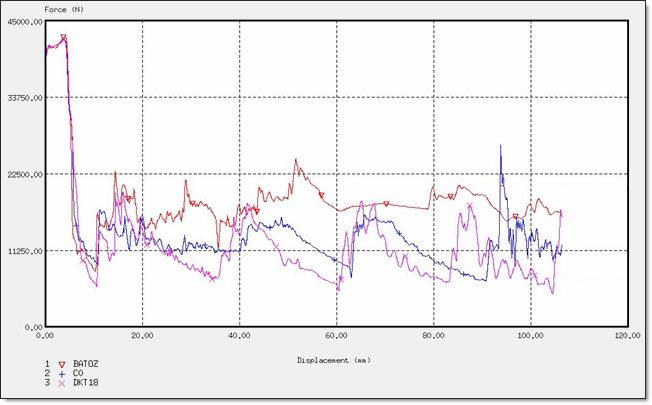

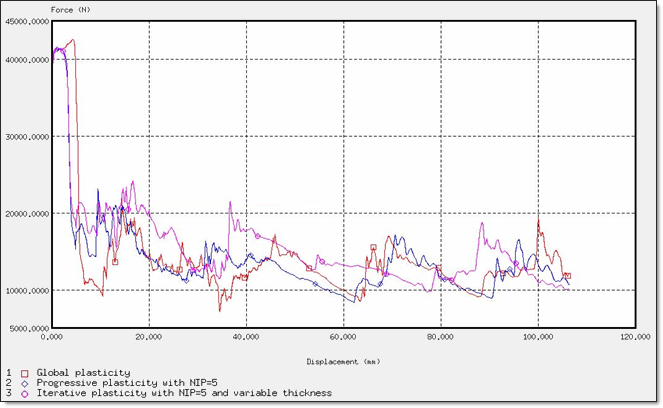

- Crushing force versus displacement

The crushing force corresponds to the normal force in the Z-direction of the impactor (rigid wall), multiplied by 4 due to symmetry.

For comparison, displacement corresponds to the Z-direction motion of the rigid wall's main node.

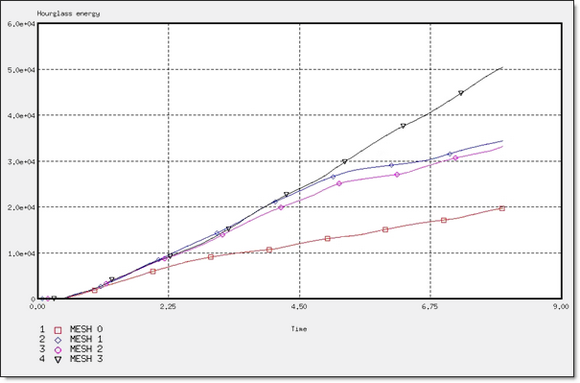

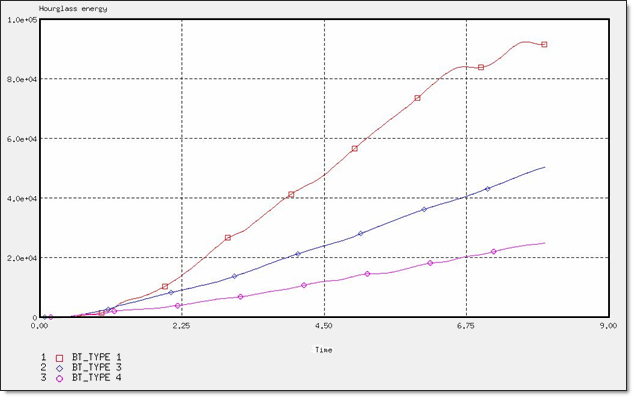

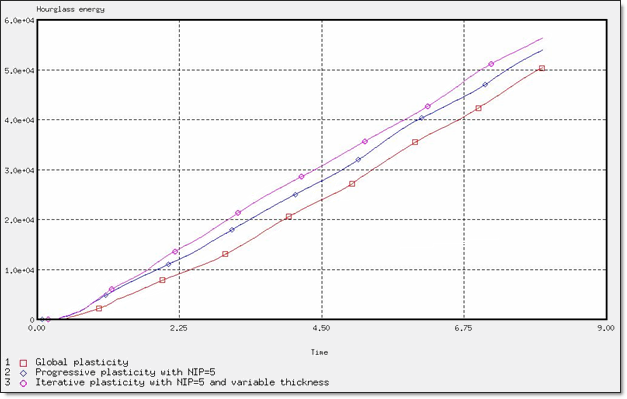

- Hourglass energy

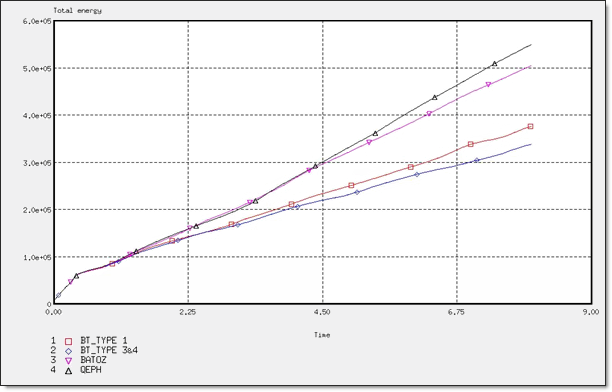

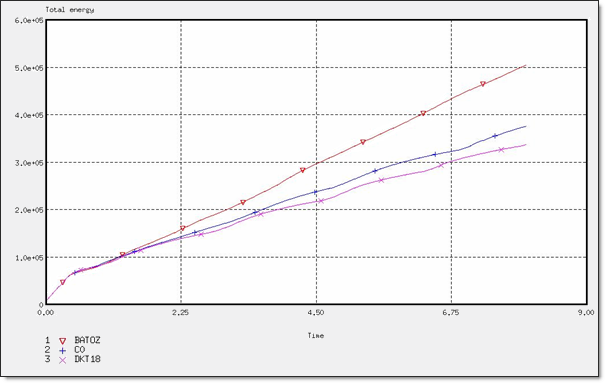

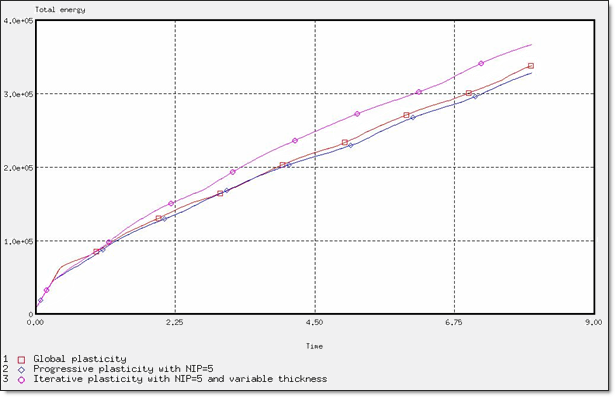

- Total energy

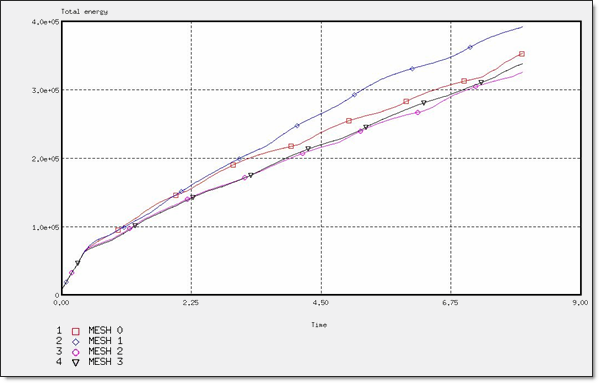

Total absorption energy is the sum of internal energy and hourglass energy.

Mesh Influence of a Given Shell Using Global Plasticity and BT_TYPE3 Formulation

Figure 4. Total Energy for a BT_TYPE3 Formulation

Figure 5. Hourglass Energy for a BT_TYPE3 Formulation

Figure 6. Force for a BT_TYPE3 Formulation

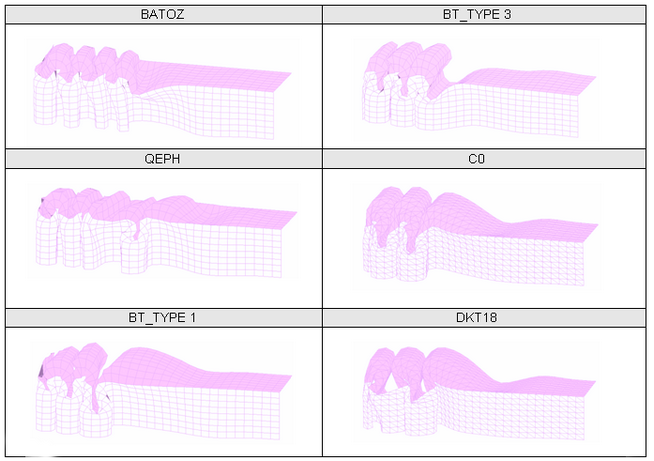

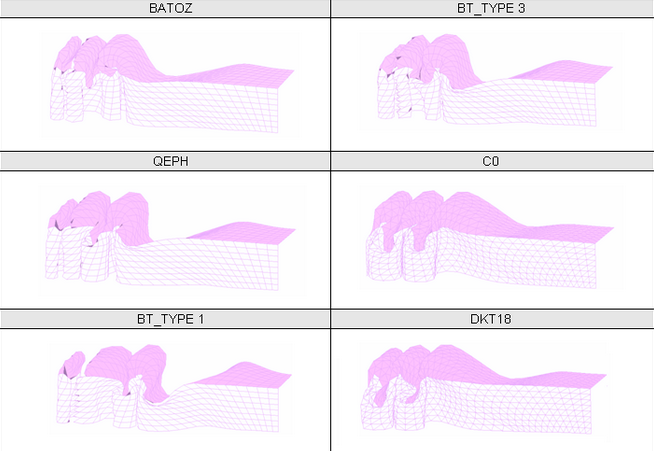

Influence of Element Formulation Using Mesh 1 and Global Plasticity

Figure 7. Total Energy for Different Element Formulation

Figure 8. Total Energy for Different Element Formulation

Figure 9. Hourglass Energy for Different BT Element Formulation

Figure 10. Force for Different Element Formulation

Figure 11. Force for Different Element Formulation

Influence of Plasticity Options Using Mesh 0 and BT_TYPE3 Formulation

Figure 12. Total Energy

Figure 13. Hourglass Energy

Figure 14. Crushing Force

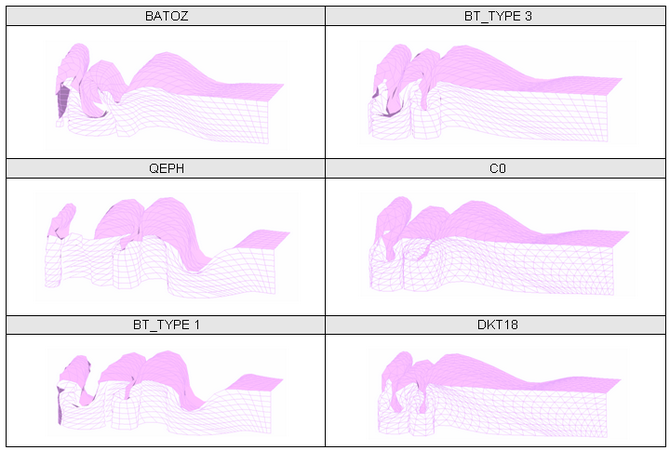

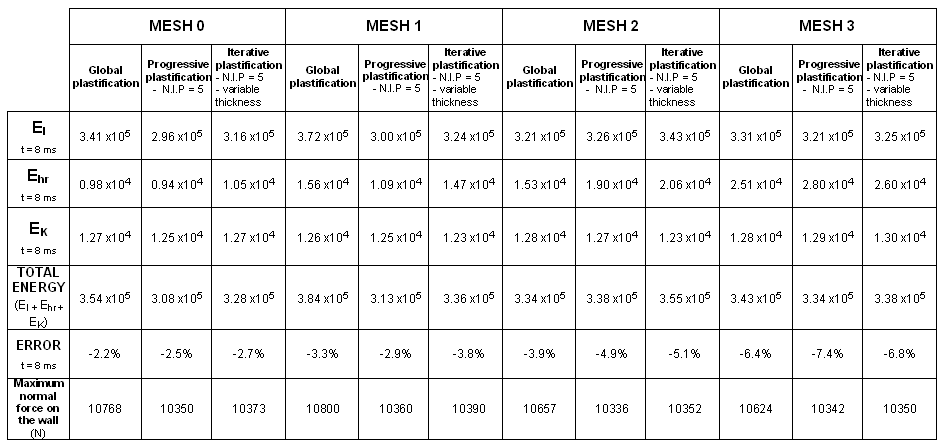

Figure 15. MESH 0

Figure 16. MESH 1

Figure 17. MESH 2

Figure 18. MESH 3

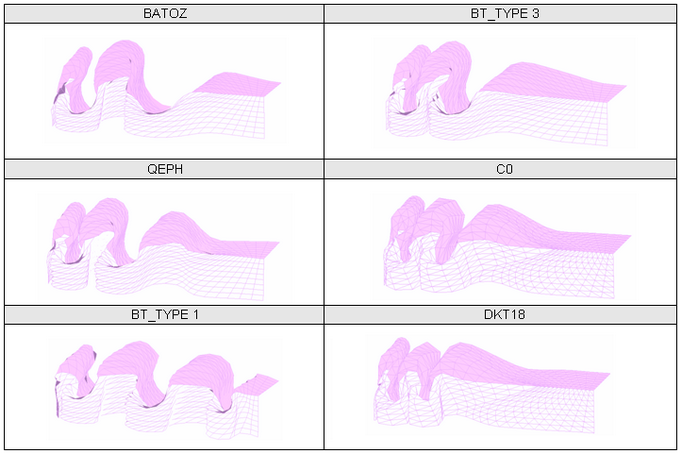

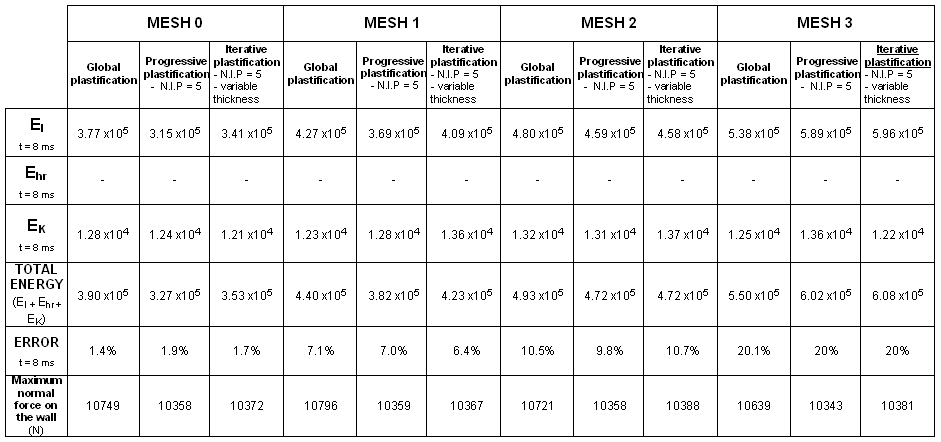

Figure 19. Formulation: BT_TYPE1

Figure 20. Formulation: BT_TYPE3

Figure 21. Formulation: BT_TYPE4

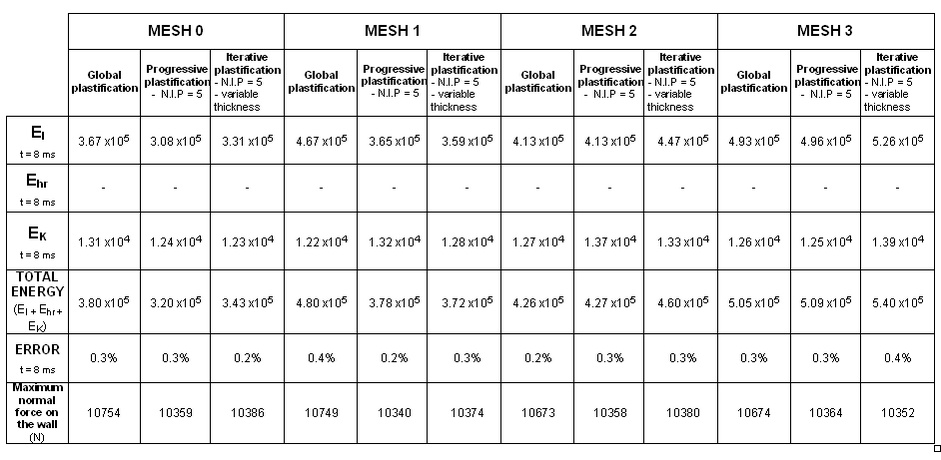

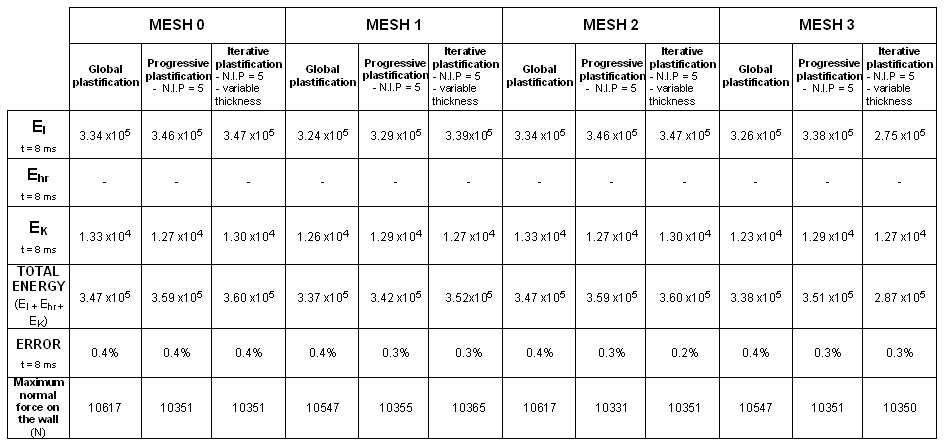

Figure 22. Formulation: QEPH

Figure 23. Formulation: BATOZ

Figure 24. Formulation: DKT18

Figure 25. Formulation: C0

Conclusion

The crash of a box beam using several meshes and finite element formulations was studied in detail. The simulation results for uniform, mapped and transit meshes are classified and compared for each different shell formulation. The results obtained illustrate the sensitivity of the shell elements with respect to the quality of the mesh for a typical crash problem.