This law is a constitutive model for predicting the nonlinear time dependency of

elastomer like materials. It uses a polynomial material model for the hyperelastic material

response and the Bergstrom-Boyce material model to represent the nonlinear viscoelastic time

dependent material response.

This law is only compatible with solid elements.

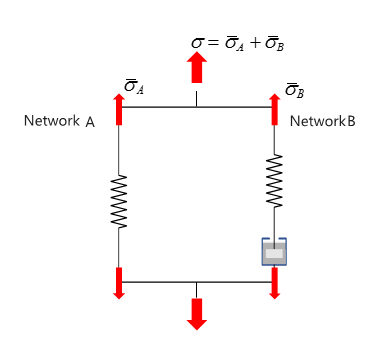

The response of the material can be represented using two parallel networks A and B.

Network A is the equilibrium network with a nonlinear hyperelastic component. In

Network B, a nonlinear hyperelastic component is in series with a nonlinear

viscoelastic flow element, and hence, is time-dependent network.

Figure 1.

Material Parameters

The same polynomial strain energy density formulation is used for the hyperelastic

components in both networks. In Network B, it is scaled by a factor

S

b

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacaWGtbWaaS

baaSqaaiaadkgaaeqaaaaa@384A@

. The strain energy density is then written for the

hyperelastic component of the network.

(1)

W

A

=

∑

i

+

j

=

1

3

C

i

j

(

I

¯

1

−

3

)

i

⋅

(

I

¯

2

−

3

)

j

+

∑

i

=

1

3

1

D

i

(

J

−

1

)

2

i

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacaWGxbWaaS

baaSqaaiaadgeaaeqaaOGaeyypa0ZaaabCaeaacaWGdbWaaSbaaSqa

aiaadMgacaWGQbaabeaakmaabmaabaGabmysayaaraWaaSbaaSqaai

aaigdaaeqaaOGaeyOeI0IaaG4maaGaayjkaiaawMcaamaaCaaaleqa

baGaamyAaaaakiabgwSixpaabmaabaGabmysayaaraWaaSbaaSqaai

aaikdaaeqaaOGaeyOeI0IaaG4maaGaayjkaiaawMcaamaaCaaaleqa

baGaamOAaaaaaeaacaWGPbGaey4kaSIaamOAaiabg2da9iaaigdaae

aacaaIZaaaniabggHiLdGccqGHRaWkdaaeWbqaamaalaaabaGaaGym

aaqaaiaadseadaWgaaWcbaGaamyAaaqabaaaaOWaaeWaaeaacaWGkb

GaeyOeI0IaaGymaaGaayjkaiaawMcaamaaCaaaleqabaGaaGOmaiaa

dMgaaaaabaGaamyAaiabg2da9iaaigdaaeaacaaIZaaaniabggHiLd

aaaa@614A@

and

(2)

W

B

=

S

b

⋅

W

A

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacaWGxbWaaS

baaSqaaiaadkeaaeqaaOGaeyypa0Jaam4uamaaBaaaleaacaWGIbaa

beaakiabgwSixlaadEfadaWgaaWcbaGaamyqaaqabaaaaa@3F4B@

Where,

I

¯

1

=

λ

¯

1

2

+

λ

¯

2

2

+

λ

¯

3

2

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaaceWGjbGbae

badaWgaaWcbaGaaGymaaqabaGccqGH9aqpcuaH7oaBgaqeamaaDaaa

leaacaaIXaaabaGaaGOmaaaakiabgUcaRiqbeU7aSzaaraWaa0baaS

qaaiaaikdaaeaacaaIYaaaaOGaey4kaSIafq4UdWMbaebadaqhaaWc

baGaaG4maaqaaiaaikdaaaaaaa@4567@

I

¯

2

=

λ

¯

1

−

2

+

λ

¯

2

−

2

+

λ

¯

3

−

2

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaaceWGjbGbae

badaWgaaWcbaGaaGOmaaqabaGccqGH9aqpcuaH7oaBgaqeamaaDaaa

leaacaaIXaaabaGaeyOeI0IaaGOmaaaakiabgUcaRiqbeU7aSzaara

Waa0baaSqaaiaaikdaaeaacqGHsislcaaIYaaaaOGaey4kaSIafq4U

dWMbaebadaqhaaWcbaGaaG4maaqaaiabgkHiTiaaikdaaaaaaa@482F@

λ

¯

i

=

J

−

1

3

λ

i

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGafq4UdWMbae

badaWgaaWcbaGaamyAaaqabaGccqGH9aqpcaWGkbWaaWbaaSqabeaa

cqGHsisldaWcaaqaaiaaigdaaeaacaaIZaaaaaaakiabeU7aSnaaBa

aaleaacaWGPbaabeaaaaa@4036@

C

i

j

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacaWGdbWaaS

baaSqaaiaadMgacaWGQbaabeaaaaa@3930@

and

D

i

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacaWGebWaaS

baaSqaaiaadMgaaeqaaaaa@3842@

Material parameters

The hyperelastic component the Cauchy stress is computed as:

(3)

σ

i

=

λ

i

J

∂ W

∂

λ

i

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaeq4Wdm3aaS

baaSqaaiaadMgaaeqaaOGaeyypa0ZaaSaaaeaacqaH7oaBdaWgaaWc

baGaamyAaaqabaaakeaacaWGkbaaamaalaaabaGaeyOaIyRaam4vaa

qaaiabgkGi2kabeU7aSnaaBaaaleaacaWGPbaabeaaaaaaaa@4421@

The total stress is the summer of stress in network A and network B.

Figure 2.

σ =

σ

¯

A

+

σ

¯

B

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaeq4WdmNaey

ypa0Jafq4WdmNbaebadaWgaaWcbaGaamyqaaqabaGccqGHRaWkcuaH

dpWCgaqeamaaBaaaleaacaWGcbaabeaaaaa@3F47@

Since

W

B

=

S

b

⋅

W

A

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacaWGxbWaaS

baaSqaaiaadkeaaeqaaOGaeyypa0Jaam4uamaaBaaaleaacaWGIbaa

beaakiabgwSixlaadEfadaWgaaWcbaGaamyqaaqabaaaaa@3F4B@

, then

σ

¯

B

=

S

b

⋅

σ

¯

A

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGafq4WdmNbae

badaWgaaWcbaGaamOqaaqabaGccqGH9aqpcaWGtbWaaSbaaSqaaiaa

dkgaaeqaaOGaeyyXICTafq4WdmNbaebadaWgaaWcbaGaamyqaaqaba

aaaa@40E1@

and total stress is

σ

=

(

1

+

S

b

)

⋅

σ

¯

A

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaeq4WdmNaey

ypa0JaaiikaiaaigdacqGHRaWkcaWGtbWaaSbaaSqaaiaadkgaaeqa

aOGaaiykaiabgwSixlqbeo8aZzaaraWaaSbaaSqaaiaadgeaaeqaaa aa@42C2@

.

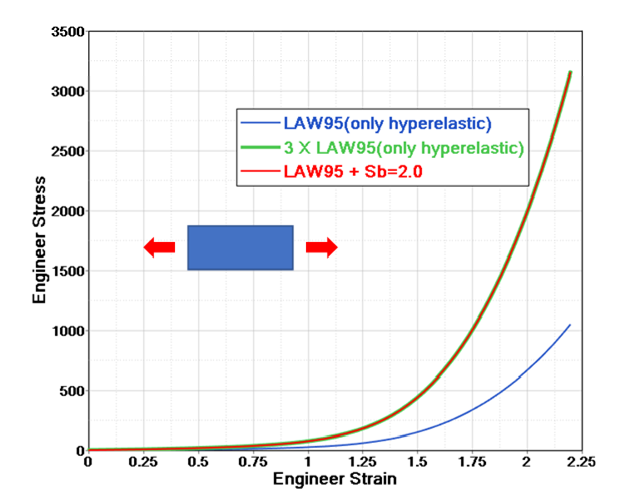

For example, in one tensile test. If use

S

b

=

2

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaam4uamaaBa

aaleaacaWGIbaabeaakiabg2da9iaaikdaaaa@39AE@

, the stress is 3 times of the one without

considering viscous (which means only considered hyperelastic).

Figure 3.

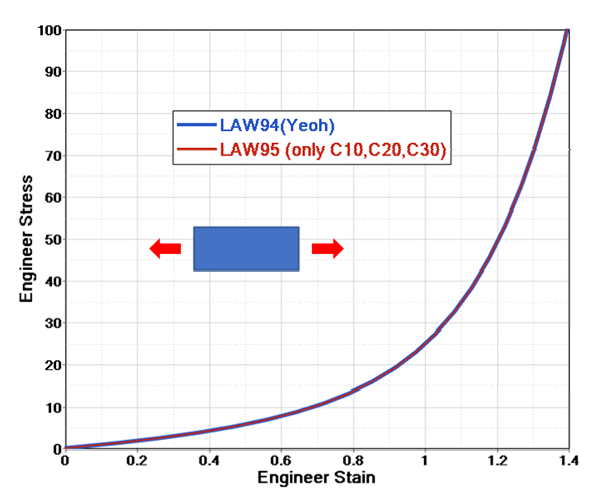

For special values of

C

i

j

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacaWGdbWaaS

baaSqaaiaadMgacaWGQbaabeaaaaa@3930@

, the polynomial model can be reduced to the

following material models.

Yeoh:

j

=

0

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaamOAaiabg2

da9iaaicdaaaa@38A5@

Where,

C

10

,

C

20

,

C

30

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaam4qamaaBa

aaleaacaaIXaGaaGimaaqabaGccaGGSaGaam4qamaaBaaaleaacaaI

YaGaaGimaaqabaGccaGGSaGaam4qamaaBaaaleaacaaIZaGaaGimaa

qabaaaaa@3EA8@

are not zero.

Figure 4.

Mooney-Rivlin:

i

+

j

=

1

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaamyAaiabgU

caRiaadQgacqGH9aqpcaaIXaaaaa@3A76@

Where,

C

10

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaam4qamaaBa

aaleaacaaIXaGaaGimaaqabaGccaGGSaGaam4qamaaBaaaleaacaaI

YaGaaGimaaqabaGccaGGSaGaam4qamaaBaaaleaacaaIZaGaaGimaa

qabaaaaa@3EA8@

and

C

01

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaam4qamaaBa

aaleaacaaIXaGaaGimaaqabaGccaGGSaGaam4qamaaBaaaleaacaaI

YaGaaGimaaqabaGccaGGSaGaam4qamaaBaaaleaacaaIZaGaaGimaa

qabaaaaa@3EA8@

are not zero and

D

2

=

D

3

=

0

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaamiramaaBa

aaleaacaaIYaaabeaakiabg2da9iaadseadaWgaaWcbaGaaG4maaqa

baGccqGH9aqpcaaIWaaaaa@3C33@

.

Neo-Hookean: Only

C

10

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaam4qamaaBa

aaleaacaaIXaGaaGimaaqabaGccaGGSaGaam4qamaaBaaaleaacaaI

YaGaaGimaaqabaGccaGGSaGaam4qamaaBaaaleaacaaIZaGaaGimaa

qabaaaaa@3EA8@

and

D

1

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaamiramaaBa

aaleaacaaIXaaabeaaaaa@37A6@

are not zero.

Where,

C

i

j

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacaWGdbWaaS

baaSqaaiaadMgacaWGQbaabeaaaaa@3930@

and

D

i

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacaWGebWaaS

baaSqaaiaadMgaaeqaaaaa@3842@

Material parameters which can be calculated by completing a curve fit

for quasi-static material test data.

RD-E: 5600 Hyperelastic Material with Curve Input , contains a

curve fit example for Mooney-Rivlin and Yeoh material models.

D

1

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaamiramaaBa

aaleaacaaIXaaabeaaaaa@37A6@

can be calculated from the bulk modulus or left

blank.

The initial shear modulus and the bulk modulus are computed as:

(4)

μ = 2 (

S

b

+ 1

) (

C

10

+

C

01

)

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacqaH8oqBcq

GH9aqpcaaIYaWaaeWaaeaacaWGtbWaaSbaaSqaaiaadkgaaeqaaOGa

ey4kaSIaaGymaaGaayjkaiaawMcaamaabmaabaGaam4qamaaBaaale

aacaaIXaGaaGimaaqabaGccqGHRaWkcaWGdbWaaSbaaSqaaiaaicda

caaIXaaabeaaaOGaayjkaiaawMcaaaaa@4643@

and

(5)

K =

2

D

1

(

1 +

S

b

)

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacaWGlbGaey

ypa0ZaaSaaaeaacaaIYaaabaGaamiramaaBaaaleaacaaIXaaabeaa

aaGcdaqadaqaaiaaigdacqGHRaWkcaWGtbWaaSbaaSqaaiaadkgaae

qaaaGccaGLOaGaayzkaaaaaa@3FD6@

If the bulk modulus of the material is known,

D

1

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaamiramaaBa

aaleaacaaIXaaabeaaaaa@37A6@

can be calculated, or if

D

1

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaamiramaaBa

aaleaacaaIXaaabeaaaaa@37A6@

=0, an incompressible material is assumed.

Viscous (Rate) Effects

The effective creep strain rate in Network B is given by:

(6)

ε

˙

B

v

= A

(

λ

˜

− 1 + ξ

)

C

σ

¯

B

τ

r e f

M

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacuaH1oqzga

GaamaaDaaaleaacaWGcbaabaGaamODaaaakiabg2da9iaadgeadaqa

daqaaiqbeU7aSzaaiaGaeyOeI0IaaGymaiabgUcaRiabe67a4bGaay

jkaiaawMcaamaaCaaaleqabaGaam4qaaaakmaalaaabaGafq4WdmNb

aebadaWgaaWcbaGaamOqaaqabaaakeaacqaHepaDdaWgaaWcbaGaam

OCaiaadwgacaWGMbaabeaaaaGcdaahaaWcbeqaaiaad2eaaaaaaa@4D1A@

Where,

λ

˜

=

I

¯

1

3

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacuaH7oaBga

acaiabg2da9maakaaabaWaaSaaaeaaceWGjbGbaebadaWgaaWcbaGa

aGymaaqabaaakeaacaaIZaaaaaWcbeaaaaa@3BE7@

σ

¯

B

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacuaHdpWCga

qeamaaBaaaleaacaWGcbaabeaaaaa@392D@

Effective stress in Network B.

A

,

ξ

,

M

,

C

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacaWGbbGaai

ilaiaaysW7cqaH+oaEcaGGSaGaaGjbVlaad2eacaGGSaGaaGjbVlaa

doeaaaa@4139@

, and

τ

r

e

f

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacqaHepaDda

WgaaWcbaGaamOCaiaadwgacaWGMbaabeaaaaa@3B1C@

Input material parameters.

The material constants

A

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaamyqaaaa@36BC@

,

M

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaamyqaaaa@36BC@

and

C

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaamyqaaaa@36BC@

are limited to a specific range of real values as

defined in the Reference Guide . If limited data is available, a trial

and error method 1

ξ

,

M

,

C

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacaWGbbGaai

ilaiaaysW7cqaH+oaEcaGGSaGaaGjbVlaad2eacaGGSaGaaGjbVlaa

doeaaaa@4139@

,

S

b

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacaWGtbWaaS

baaSqaaiaadkgaaeqaaaaa@384A@

=1.6; and

A

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaamyqaaaa@36BC@

=5. Next, compare model predictions with experimental

data for at least one strain rate and adjust

A

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaamyqaaaa@36BC@

to get a fit for the strain rate data.

1 Bergström,

J. S., and M. C. Boyce. "Constitutive modeling of the large strain time-dependent

behavior of elastomers." Journal of the Mechanics and Physics of Solids 46, no. 5

(1998): 931-954