HL-T: 1020 Multiaxial Stress-Life (S-N)

In this tutorial you will:

- Import a model to HyperLife

- Select the SN module and define its required parameters

- Create and assign a material

- Assign load histories for scaling the stresses from FEA subcases

- Evaluate and view results

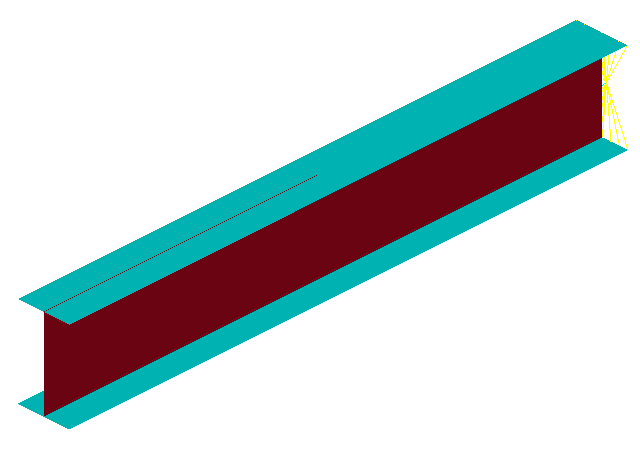

Import the Model

-

From the Home tools, Files tool group, click the Open Model tool.

Figure 1. -

From the Load model and result dialog, browse and select

HL-1020\Ibeam.h3d for the model

file.

The Load Result field is automatically populated. For this tutorial, the same file is used for both the model and the result.

-

Click Apply.

Figure 2.

Tip: Quickly import the model by dragging and

dropping the .h3d file from

a windows browser into the HyperLife

modeling window.

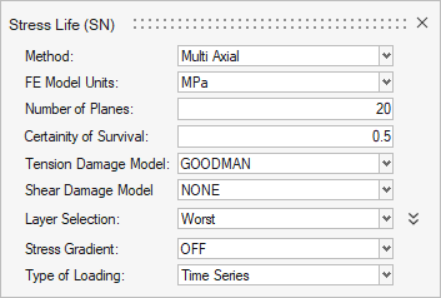

Define the Fatigue Module

-

Click the SN tool.

The SN tool should be the default fatigue module selected. If it is not, click the arrow next to the fatigue module icon to display a list of available options.

Figure 3.The SN dialog opens. -

Define the SN configuration parameters.

- Select Multi Axial as the method.

- Select MPa for the FE model units.

- Enter a value of 20 for the number of planes.

- Enter a value of 0.5 for the certainty of survival.

- Select GOODMAN for the Tension Damage Model.

- Select NONE for the Shear Damage Model.

- Select Worst for the layer selection.

- Select Time Series for the type of loading.

Figure 4. - Exit the dialog.

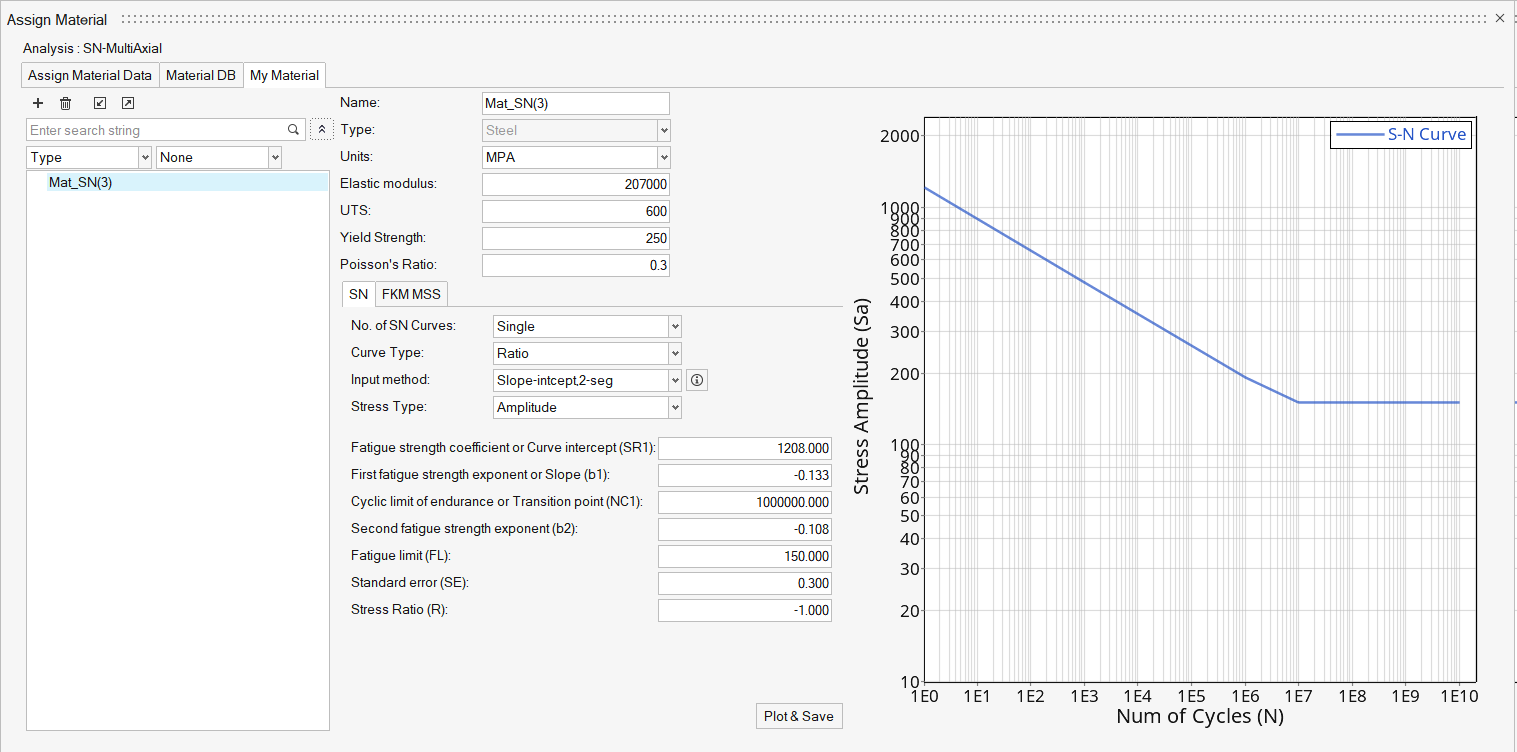

Assign Materials

-

Click the Material tool.

Figure 5.The Assign Material dialog opens. - Activate the checkboxes next to the parts Flange and Web.

-

Create a new material.

- Click the My Material tab.

-

Click

to create a new material.

to create a new material.

- Name the material Mat_SN_multiaxial.

- Set the Elastic modulus to 200000.

- Set the Input method to Slope-intcept,2-seg.

-

Accept all other default settings then click Plot &

Save.

Figure 6.

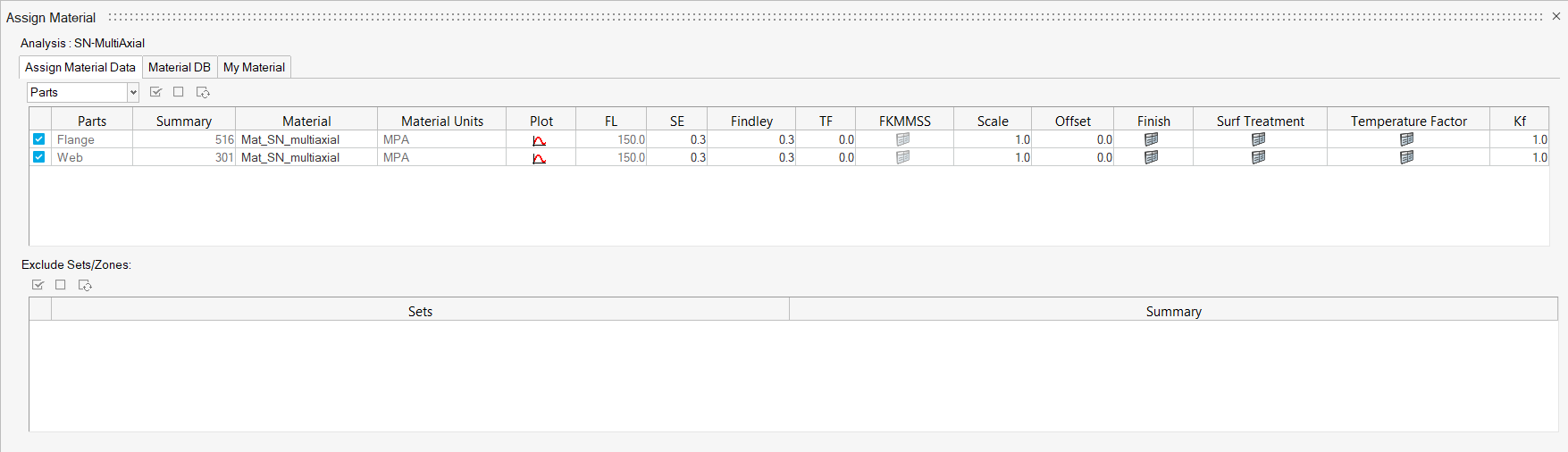

- Right-click on Mat_SN_multiaxial and select Add to Assign Material List.

-

Return to the Assign Material Data tab and select

Mat_SN_multiaxial from the Material drop-down menu

for both Flange and Web.

The Material list is populated with the materials selected from Material Database and My Material.

Figure 7. - Exit the dialog.

Assign Load Histories

-

Click the Load Map tool.

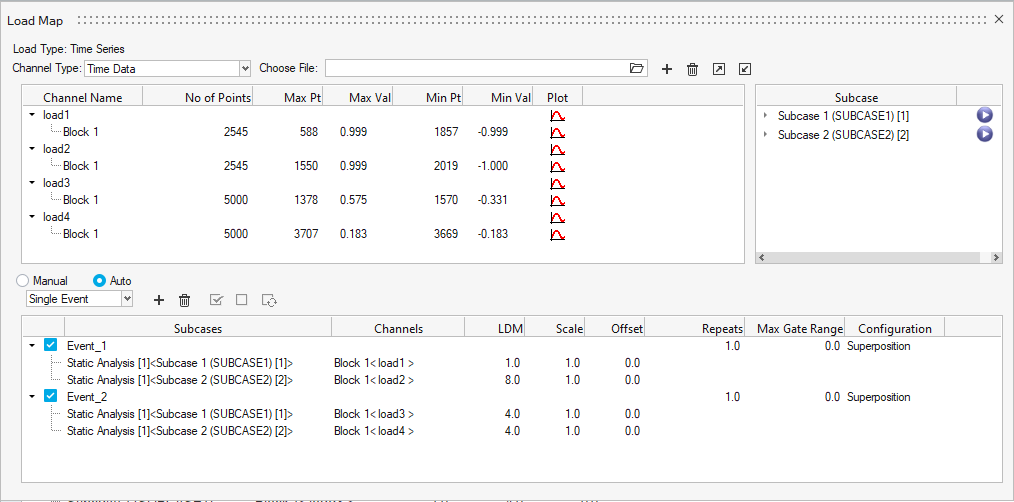

Figure 8.The Load Map dialog opens. - From the Channel Type drop-down menu at the top of the dialog, select Time Data.

-

Click

in the Choose File

field and browse for load1.csv.

in the Choose File

field and browse for load1.csv.

-

Click

to add the load case.

to add the load case.

- Repeat steps 3 and 4 for load2.csv, load3.csv, and load4.csv.

- Optional:

Click

to view a plot of the loads.

to view a plot of the loads.

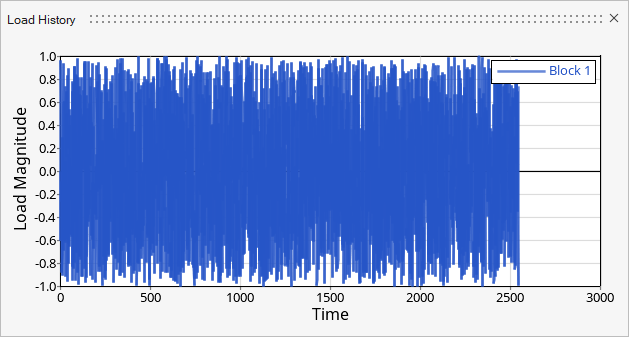

Figure 9. Load 1

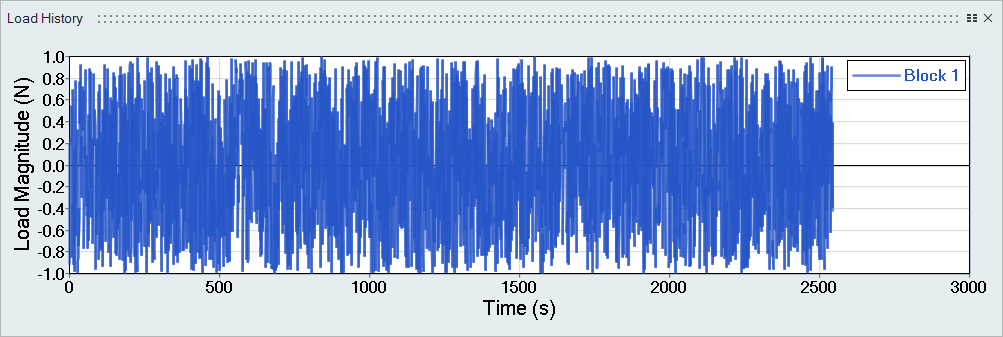

Figure 10. Load 2

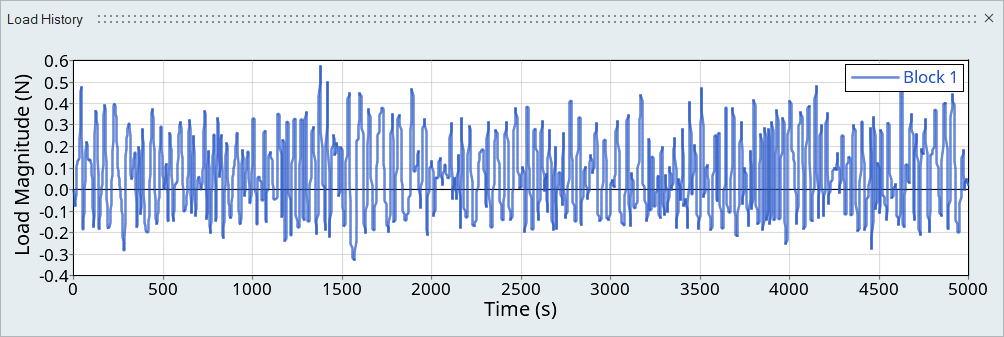

Figure 11. Load 3

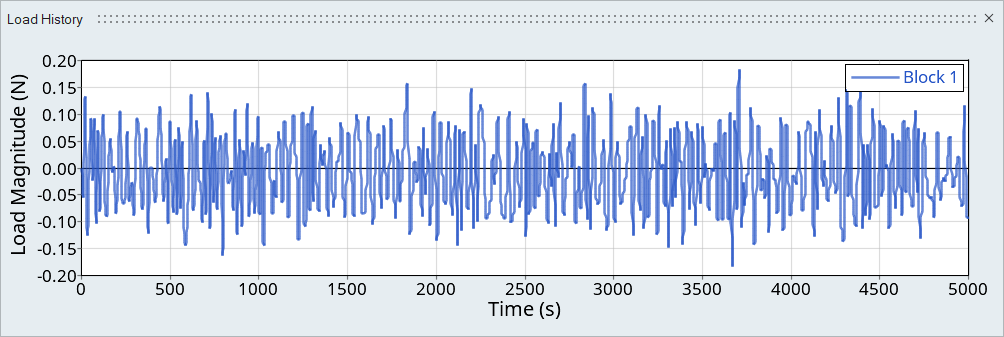

Figure 12. Load 4Tip: Expand the width of the dialog to view a clearer picture of the plot. - On the bottom half of the dialog, set the radio button to Auto for event creation.

-

Select both the load 1 (block1) and load 2

(block1) channels and Subcase 1 and

Subcase 2, then click

to create the first event.

to create the first event.

- In a similar manner, create a second event by selecting load 3 (block1), and load 4 (block1), Subcase 1, and Subcase 2.

- Activate the checkboxes for the two events.

-

Set the Scale as shown in the image below.

Figure 13. - Exit the dialog.

Evaluate and View Results

-

From the Evaluate tool group, click the

Run Analysis tool.

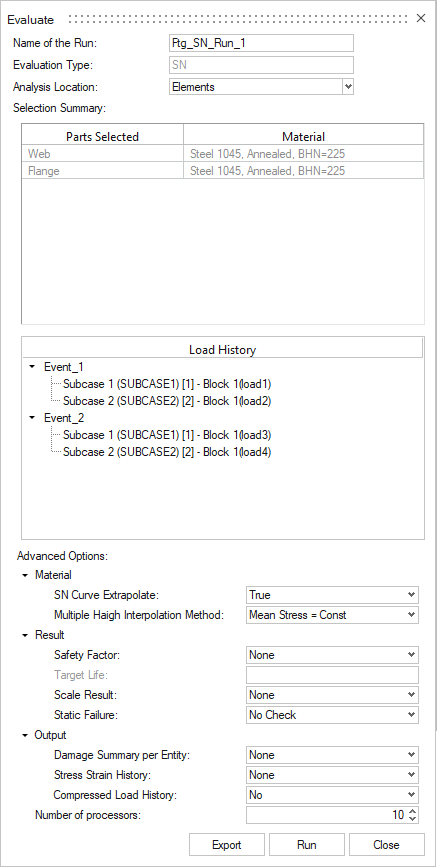

Figure 14.The Evaluate dialog opens.

Figure 15. - Optional: Enter a name for the run.

-

Click Run.

Result files are saved to the home directory and the Run Status dialog opens.

- Once the run is complete, click View Current Results.

-

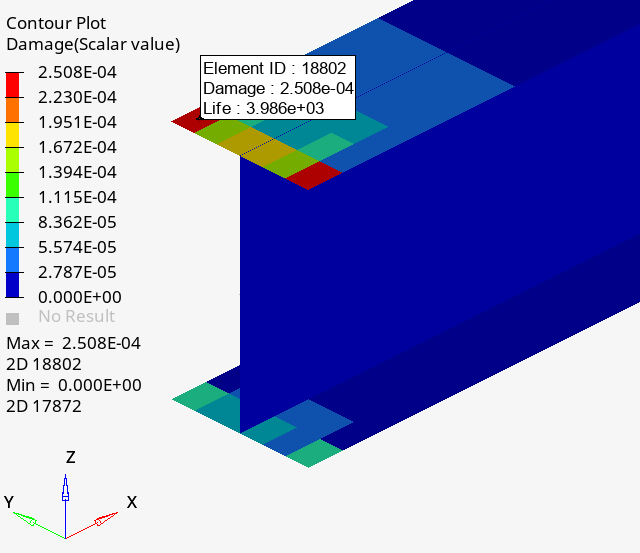

Use the Results Explorer to

visualize various types of results.

The contour below highlights the total damage (Event 1 + Event 2).

Figure 16.

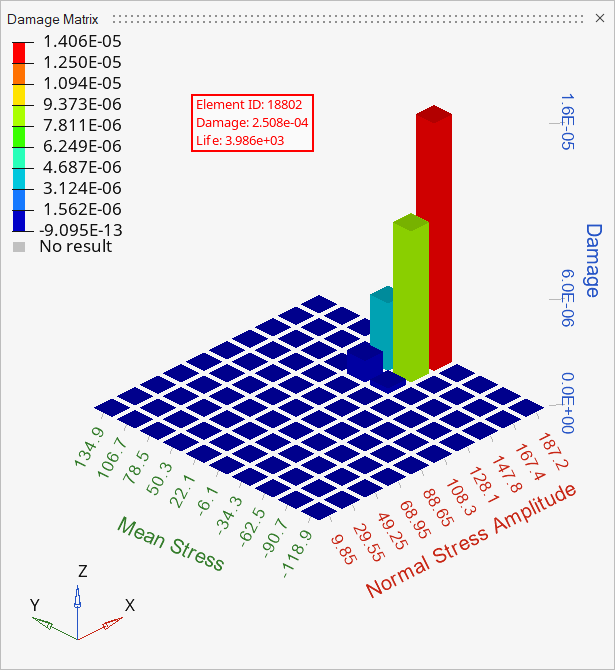

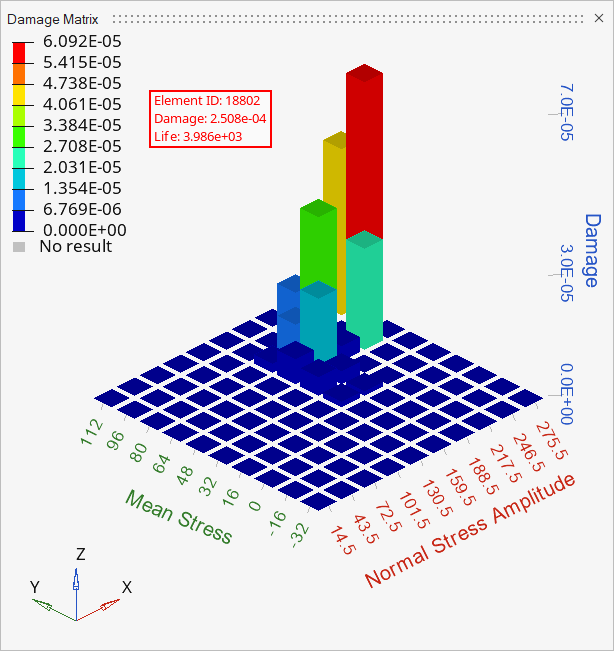

Figure 17. Event 1: Damage matrix for element 18802

Figure 18. Event 2: Damage matrix for element 18802