Solid Mesh Property Cards |

|

|

|

|

|

Solid Mesh Property Cards |

|

|

|

|

Assigning properties to solid mesh is the first step in the model setup process for Moldex3D solver.

| • | The various types of solid meshes that are supported are cavity, cold runner, hot runner, moldbase, mold insert and part insert, heating rod and coolant channel. |

| • | Cavity, cold runner and hot runner solid meshes fall in the category of plastic elements. |

| • | Moldbase and mold insert meshes fall in the category of moldbase elements. |

| • | Coolant channels and heating rod meshes fall in the category of coolant channel. |

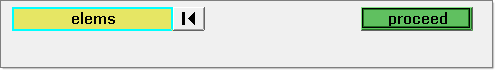

From the Create Property Cards submenu, click Solid Mesh. A selector for elements appears as shown below.

The Solid Mesh utility can be used for assigning as well editing property cards for solid elements. If the selected elements already have a property card attached to them, then the dialog shows the relevant mesh type. The color button sets the color of the component collector to which the selected elements will be moved. All the types of solid meshes with their assignment procedures and attributes (if any) are described below.

A cavity solid mesh property does not have any attributes. If selected elements are defined as cavity solid mesh, the elements are transferred to a component named Cavity. A property with the same name is also created and assigned to the above elements.

Cold Runner Solid Mesh

Cold runner solid mesh does not have any attributes. If selected elements are defined as cold runner solid mesh, the elements are transferred to a component named ColdRunner. A property named Cold_Runner is also created and assigned to the elements.

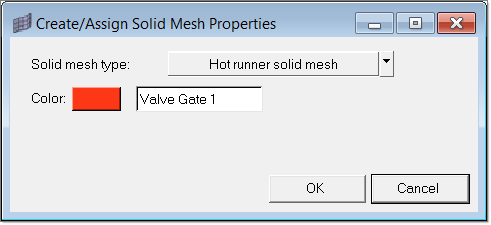

Hot runner solid mesh can be defined with a valve gate or none valve gate. The valve gate can be specified in a manner as shown below.

The selected elements are transferred to a component named HotRunner. A property named Hot_Runner is also created and assigned to the selected elements. If part of the runner is defined with valve gate, then the new property would be named as Hot_Runner.1.

Coolant channel solid mesh does not have any attributes. Selected elements will be transferred to a component named CoolantChannel. A property name Coolant_Channel is also created and assigned to these elements.

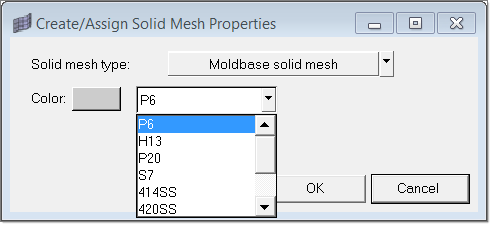

Moldbase solid mesh can be defined by specifying a material. The material can be selected as shown below.

Selected elements are transferred to a component named MoldBase. A property with the same name is also created and assigned with the elements. A moldbase can defined with multiple materials. In that case, properties with names such as MoldBase.1, MoldBase.2 and so on will be created. The number of properties created will be equal to the number of different materials specified for the moldbase.

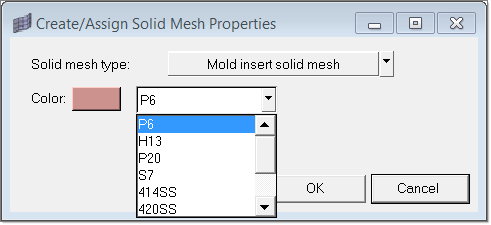

Mold insert solid mesh is identical in behavior to moldbase solid mesh. The component to which the elements are moved is named MoldInsert. Property names are Mold_Insert.1, Mold_Insert.2 and so on.

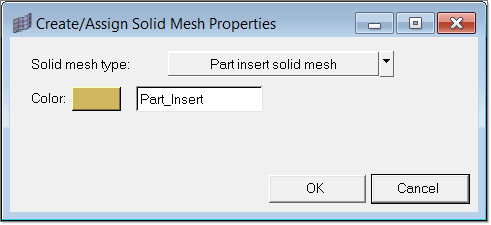

Part insert solid mesh is defined by specifying the material. There can be multiple part inserts in a model.

Selected elements are moved to a component name PartInsert. Properties are created with names such as Part_Insert.1, Part_Insert.2 and so on.

Heating rod solid mesh does not any attributes. Selected elements are moved to a component named HeatingRod. A property named Heating_Rod is also created and assigned to the selected elements.