/MAT/LAW71

Block Format Keyword This law describes the behavior of superelastic materials. It allows modeling the behavior of the shape memory alloys (such as Nitinol).

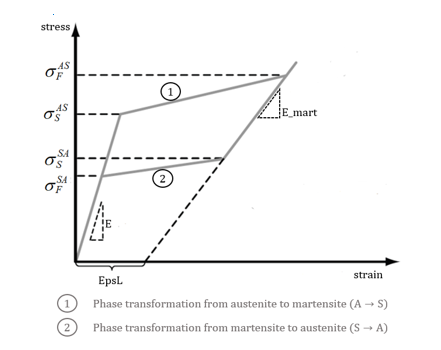

The particularity of these materials is that all of the strain is recovered upon unloading even when large deformations are reached. Besides, the material shows a hysteretic response in a complete loading-unloading cycle. The full recovery is due to phase change in the microstructure. The model is based on the work of Auricchio et al. 1997. This law is compatible with beam (/PROP/TYPE18 (INT_BEAM) only), solid and shell elements.

Format

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| /MAT/LAW71/mat_ID/unit_ID | |||||||||

| mat_title | |||||||||

| E | E_mart | ||||||||

| EpsL | CAS | CSA | TS_AS | TF_AS | |||||

| TS_SA | TF_SA | Cp | Tini | ||||||

Definition

| Field | Contents | SI Unit Example |

|---|---|---|

| mat_ID | Material

identifier. (Integer, maximum 10 digits) |

|

| unit_ID | Unit Identifier. (Integer, maximum 10 digits) |

|

| mat_title | Material

title. (Character, maximum 100 characters) |

|

| Initial

density. (Real) |

||

| E | Young's

modulus. (Real) |

|

| Poisson's

ratio. (Real) |

||

| E_mart | Martensite Young's

modulus. Default = 0.0 (Real) |

|

| Material parameter

defining the start of phase transformation from austenite to

martensite (AS). 1 (Real) |

||

| Material parameter

defining the end of phase transformation from austenite to

martensite (AS). 1 (Real) |

||

| Material parameter

defining the start of phase transformation from martensite

to austenite (SA). 1 (Real) |

||

| Material parameter

defining the end of phase transformation from martensite to

austenite (SA). 1 (Real) |

||

| Material parameter

measuring the difference in response between tension and

compression. Default = 0 (Real) |

||

| EpsL | Maximum residual

strain. 2 (Real) |

|

| CAS | Stress-Temperature

rate during loading. Default = 0 (Real) |

|

| CSA | Stress-Temperature

rate during unloading. Default = 0 (Real) |

|

| TS_AS | Reference

temperature for start of transformation (AS). Default = 298K (Real) |

|

| TF_AS | Reference

temperature for end of transformation (AS). Default = 298K (Real) |

|

| TS_SA | Reference

temperature for start of transformation (SA). Default = 298K (Real) |

|

| TF_SA | Reference

temperature for end of transformation (SA). Default = 298K (Real) |

|

| Cp | Specific heat

capacity. Default = 1030 (Real) |

|

| Tini | Initial

temperature. Default = 360 K (Real) |

Example (Metal)

#RADIOSS STARTER

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/UNIT/1

unit for mat

Mg mm s

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#- 2. MATERIALS:

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/MAT/LAW71/1/1

metal

# RHO_I

6.50E-9

# E Nu E_mart

62500 .3 51000

# sig_AS_s sig_AS_f sig_SA_s sig_SA_f alpha

450 600 300 200 0.20

# EpsL CAS CSA TS_AS TF_AS

0.045 1 1 383 343

# TS_SA TF_SA CP TINI

363 403 837 360

#ENDDATA

/END

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|Comments

- If E_mart=0, then Young's modulus is considered constant, equal to E, and not dependent on the phase fraction of the material.

- The different stresses

,

,

and

, defining the start and the end of phase

transformation, as well as the residual strain EpsL, correspond to the case

of a uniaxial tensile test:

Figure 1. - The parameter

is computed from the initial value of the

austenite to martensite phase transformation in tension

and compression

from the relation.

(1) When /MAT/LAW71 is used with beam elements, the parameter must be set to .

- The Drucker-Prager type

loading function

is introduced using the stress deviator

, the pressure

and the temperature.

(2) Two functions are defined for the start and the final point of transformation from austenite to martensite (A → S) or from martensite to austenite (S → A).(A→S) (S →A) Start point of transformation Final point of transformation Condition Evolution equation of martensite During loading: During unloading: are the material parameters. The conversion of austenite to martensite takes place when above conditions (in table) are verified.

- List of Animation output

(/ANIM/BRICK/USRI):

- USR 1= Martensite phase fraction

- USR 2= Loading function

- USR 3= Unloading function