Powertrain Modeling

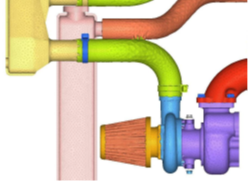

Overview

- Import CAD

- Create component sets

- Defeature CAD as necessary (Optional)

- Facet powertrain assembly

- Patch openings and review

- HX Modeling

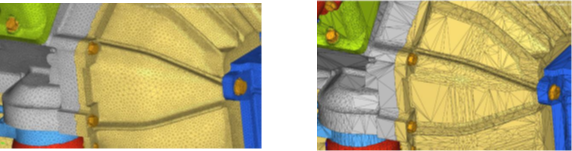

- Wrap with wrap controls (Assembly by assembly or entire underhood)

- Wrapping quality: Check for bridging and that features are captured

- Decimate (may not want to decimate too much)

Process

- Import associated CAD for the powertrain:

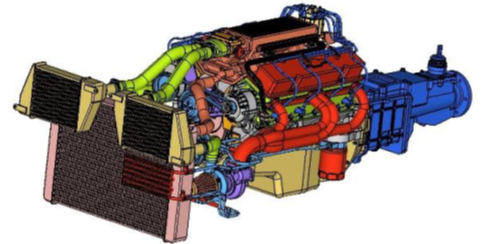

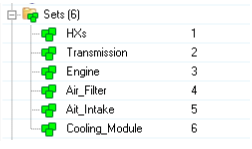

Figure 1. - Create sets based on analysis:

- Tools pull down > Create sets of components

- Model browser > Show/Hide components by sets for further steps

- Use sets to select component -> by sets

Figure 2.

- Defeature Geometry (Optional):

- Simplify model to avoid modeling unnecessary features like logos, solid holes, fillets, and so on

- Find small parts and delete them

- Use find_smallParts.tcl script

- Define 10 as threshold to find small parts (Generally nuts and bolts)

- It will create a set will small parts based on tolerance

- Right-click Isolate only to review the parts

- F2 to open delete panel Select parts to delete

- Remove logo (Geometry --> Auto cleanup)

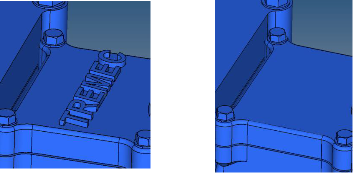

Figure 3.- Select logo and surrounding surface

- Selection does not need to be precise

- It should cover all logo surfaces and surrounding surfaces

- You can select all surfaces as well

- Measure logo height beforehand to define in this utility

- Simplify parts

- Select logo and surrounding surface

- Solid hole removal

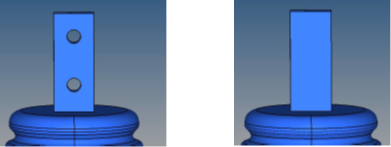

Figure 4.- Use solid hole removal in Geometry ribbon

- In edit parameters, turn on the option to remove solid hole

- Define maximum radius as 20 (Choose radius according to selection)

- Create primitive shapes to model complex parts with cylinder, sphere or block

- Tessellate CAD:

- Once done with geometry editing tool, tessellate the CAD to further

work on mesh-based tools like wrapper, hole gap patch, and so on

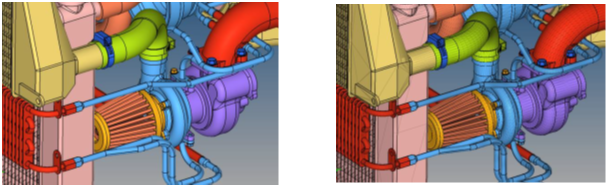

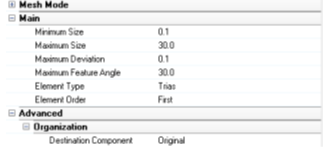

Figure 5. - Use rigid body mesher to tessellate

- Define following parameters (for model in mm scale)

Figure 6. - Tips:

- Change maximum and minimum sizes according to scale of the model and level of details required.

- Review tessellated mesh

- Review that tessellation captures original shape as required

- Review free edges:

- Tools > Edges > Free edges

- Delete geometry to make model lighter (Surfaces and Solids)

- Once done with geometry editing tool, tessellate the CAD to further

work on mesh-based tools like wrapper, hole gap patch, and so on

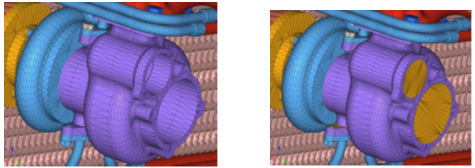

- Patch:

- Patch complex areas, gaps, solid opening

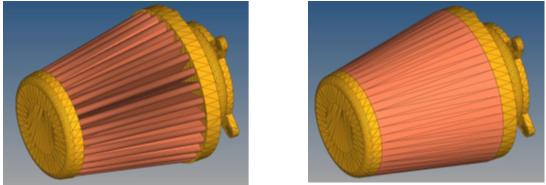

Figure 7. - Patch openings, solid holes (): Here you need to close opening of pipes, solid

holes so the wrapper does not go inside parts; if this happens, you

get exterior surfaces as wrap results

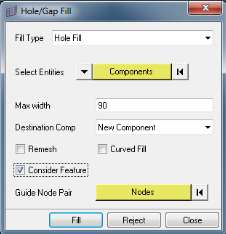

- Switch to Fill mode to “Hole fill”

Figure 8. - Select all components

- Turn on Consider features which will consider solid holes as well.

- Define hole width: 100

- Measure the hole length you want to close and define it as maximum width

- For powertrain and underhood cases start with maximum width as 50

- Review patches. Delete patch elements if not required

- Manual patch as required by selecting Faces or edges instead of components

- Switch to Fill mode to “Hole fill”

- Close gaps in the model

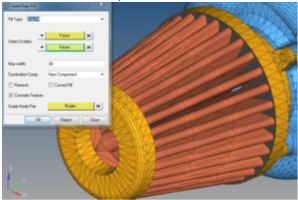

Figure 9.- Switch to Fill mode to “Gap fill”

Figure 10. - Select opposite faces one in each group

- Turn on Consider features.

- Measure the gap length you want to close and define it as maximum width

- Switch to Fill mode to “Gap fill”

- Cover slots so that they are not exposed to wrapper; they are not

useful for analysis

Figure 11.- Switch to Fill mode to “Patch fill”

Figure 12. - Select Nodelist

- Select nodes which covers shape. For a flat area, 4 nodes should be enough

- Switch to Fill mode to “Patch fill”

- Patch complex areas, gaps, solid opening

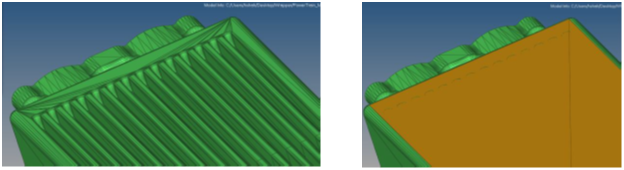

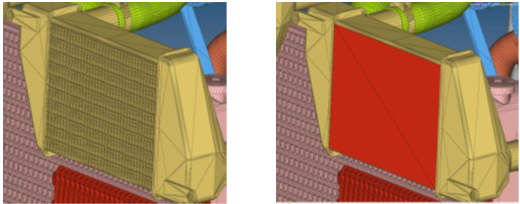

- Model Heat exchanger (HXs):

- When you are given detailed HXs with fins and tubes, model them

using boxes

- Create HXs boxes

- Delete the fins and tubes

- Only retain HX shroud

- Do not include HX box components in wrapping

- After wrapping, connect HX box and wrapped parts (required

for AcuSolve only)

- Mesh pull down > Boolean

- Select all wrapped components and HX boxes

- Define Boxes as master > Boolean

- Create HX boxes

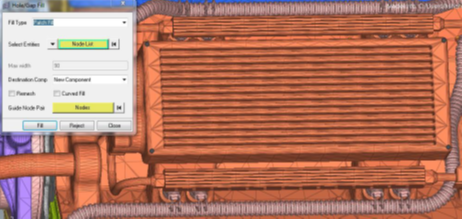

Figure 13.- Mesh pull down > Hole/Gap Fill

- Switch to Fill mode to “Patch fill”

- Switch selection to Nodelist

- Select four corner nodes which covers fins and tubes

- Do it for both inlet and outlet

- Create a side walls using same tool

- Organize elements in appropriate components

- Use Tools panel > Translate to enclose HX in corresponding

box

Figure 14.

- When you are given detailed HXs with fins and tubes, model them

using boxes

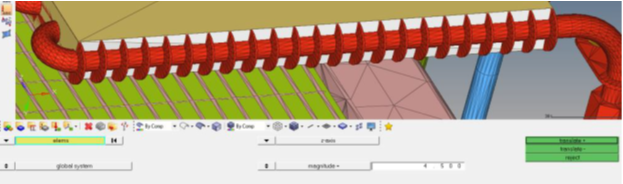

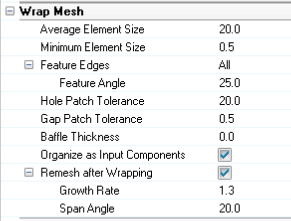

- Wrap setting - Mesh Controls:

- Define wrapper settings

- Mesh pull down > Mesh controls

- Right-click > Adaptive wrap folder > Create > Model

- Select wrapper type: external wrapper

- External wrapper for external flow analysis, for example, underhood thermal

- Cavity wrapper for internal flow analysis, for example, thermal comfort.

- Select volume definition: All

- Available options (All/Nth largest/Enclosed by node/Exclude by node) – See the help for more details

- Select components to be wrapped

- Define wrapping parameters:

Figure 15.

- Tips:

- Minimum size should be based on the smallest feature length to be captured. (Rule of thumb – minimum size = 1/3rd of smallest thickness)

- If all gaps are patched using “Hole/gap fill” tool, define

gap patch tolerance as minimum size.

- Defining bigger gap patch tolerance can create bad wrap mesh

- Define local controls if any other wrapping size is required locally

- Define Proximity Controls to avoid contacts between selected

parts

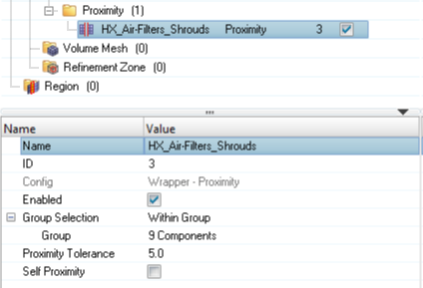

Figure 16.- Define proximity controls

- Select all HX, Air filter and neighboring shroud components

- Define search floor. Any thing less than value will be

refined

Figure 17. - Leak Detection to verify if any leaks present in the model

with given selection and parameters

- Define a source node inside the wrapping domain

- Make sure source node is enclosed properly and not close by any elements

- Define multiple target nodes outside the volumes.

- Define many target nodes and distribute them at different location

- This way you have a greater chance of finding

all possible leaks at once

Figure 18.

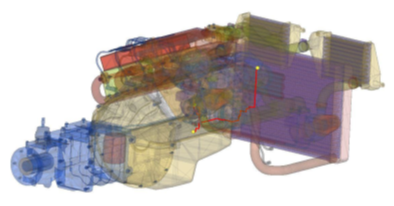

- Run wrapping:

- Right-click on adaptive wrap folder -> Mesh

- If leak detection mesh control is defined and there is a leak, it will terminate wrapping with leak path.

- Define a source node inside the wrapping domain

- Define wrapper settings

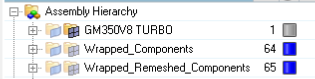

- Review wrap results:

- Review wrap results and validate it before tetmeshing. After

wrapping, there will be a new assembly creates which will contain

wrapped results

Figure 19. - Check intersections:

- 3d panel > Tetramesh > Select all wrapped components > Check 2d mesh

- Define intersection tolerance (for mm scale 0.001 and di-hedral angle as 5)

- Wrapped results mostly will not have any intersection.

- But sometimes you can see few intersections which can be resolved using 2d panel > Replace

- Check free edges and t-connection

- Tools panel > Edges > Select all wrapped components > Free edge/t-connection

- Wrapped results should not have any free edges/t-connections

- Analyze volume wrapper has created

- Use volume_analyser.tcl script

- Only display wrapped components (either wrapped or remeshed)

- It will create a sets with possible volumes and you can review each volume as well

- Review wrap results and validate it before tetmeshing. After

wrapping, there will be a new assembly creates which will contain

wrapped results

- Decimation:

- If solver is uFx/PowerFlow, it is required to have minimum element count for post processing purpose

- Decimation reduces elements count retaining sharp features intact

with minimal geometry deviation

Figure 20.- Use Decimation scripts to coarsen mesh

- Select components to decimate

- Define decimation factor: 0

- 0: Provides least deviation from input

- 1: Enables maximum possible deviation

- Define feature angle: 30

- Use Decimation scripts to coarsen mesh