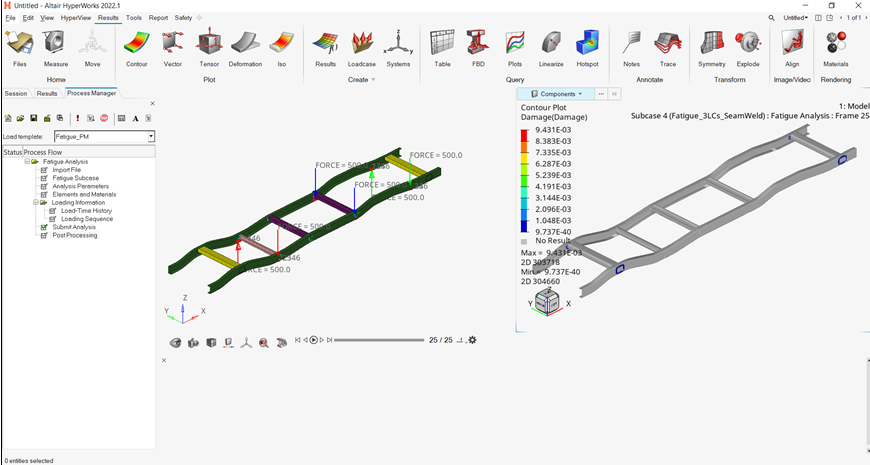

OS-HM-T: 6030 Seam Weld Fatigue (FPM) using S-N Method

The method is a hot-spot stress approach applicable to thin metal sheets.

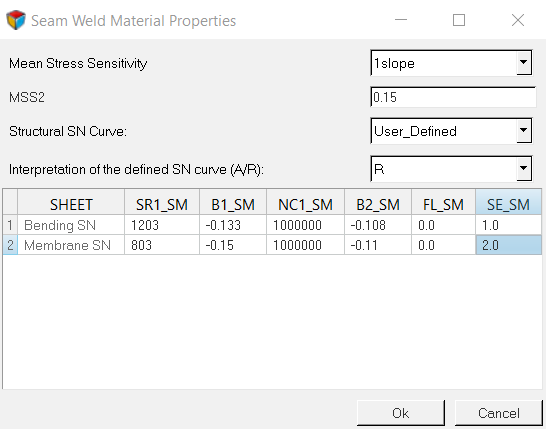

Hot-spot stress is calculated from grid point forces at the weld line. The method showed a good agreement with laboratory test results for sheet thickness between 1.0 mm and 3.0 mm. The method typically requires two SN curves. One is a bending SN curve which is dominated by bending stress, and the other is a membrane SN curve which dominated by membrane stress.

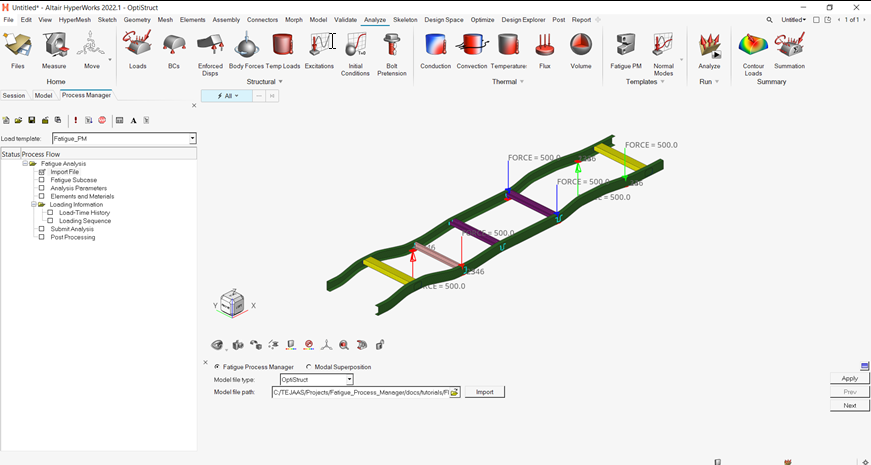

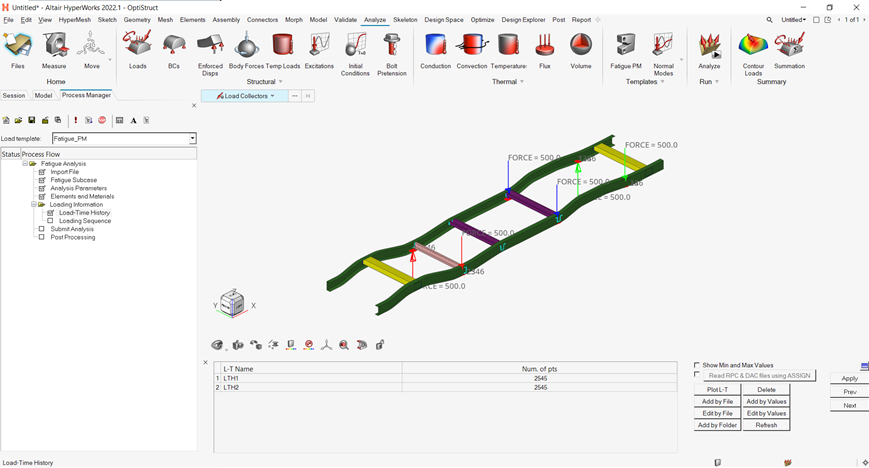

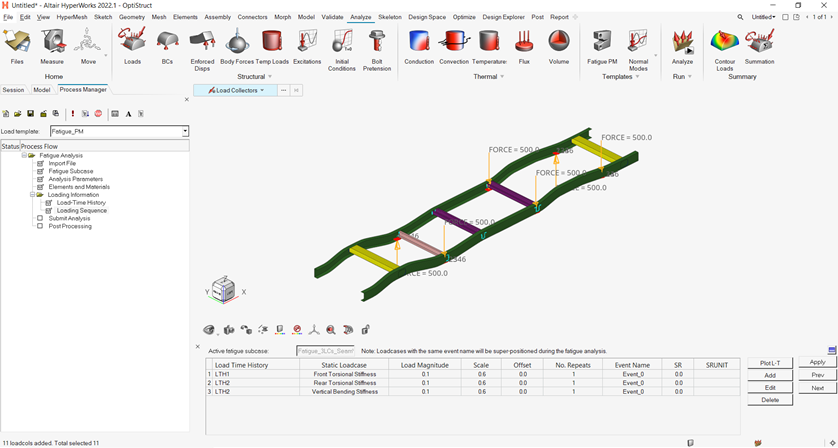

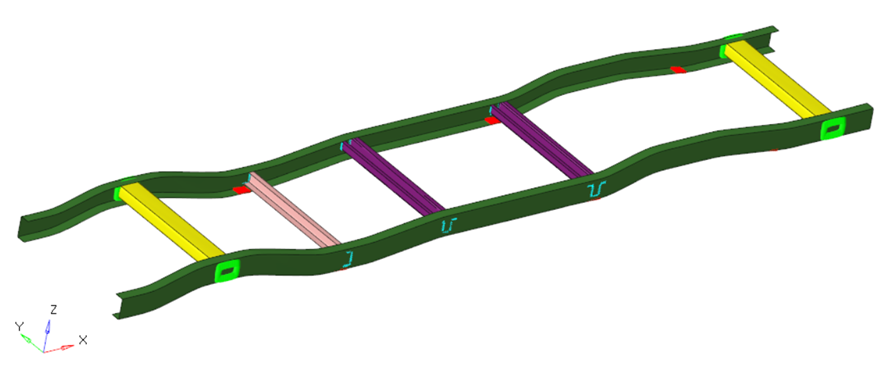

Figure 1. Automotive Frame

- Launch Fatigue Process Manager

- Import a model

- Create fatigue subcase

- Define fatigue analysis parameters

- Define fatigue elements and S-N properties

- Define load-time history and loading sequence

- Submit the job

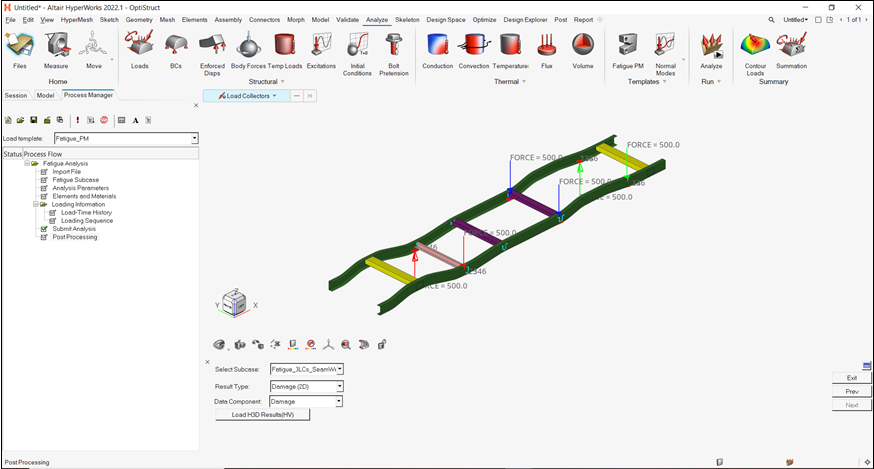

- View results summary and launch HyperView for post-processing

Launch Altair HyperWorks/HyperMesh and Process Manager

The model being used for this exercise is that of an automotive frame. The fem file consists of the 3 static load steps to which the frame is subjected to – Frontal torsion, Rear torsion and the Vertical Bending.

Import the Model

Set Up the Model

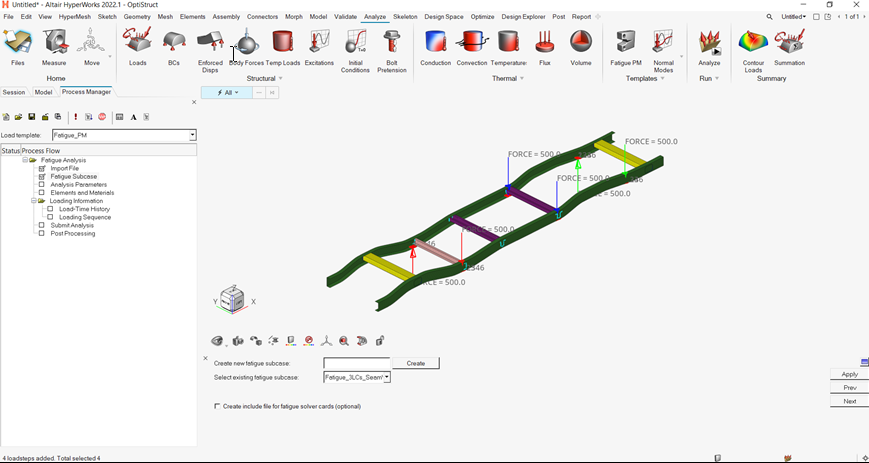

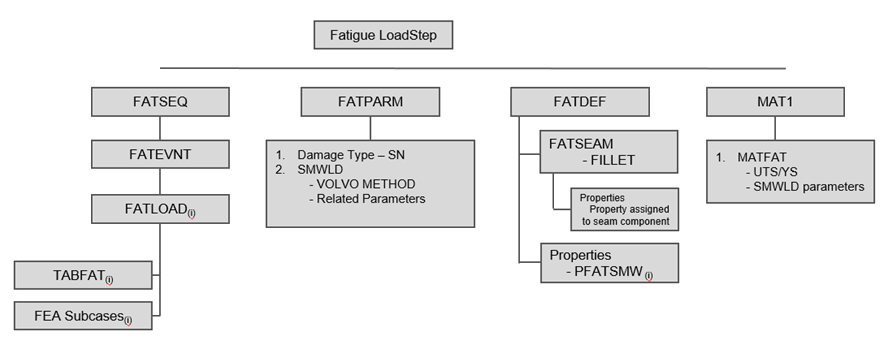

Create a Fatigue Subcase

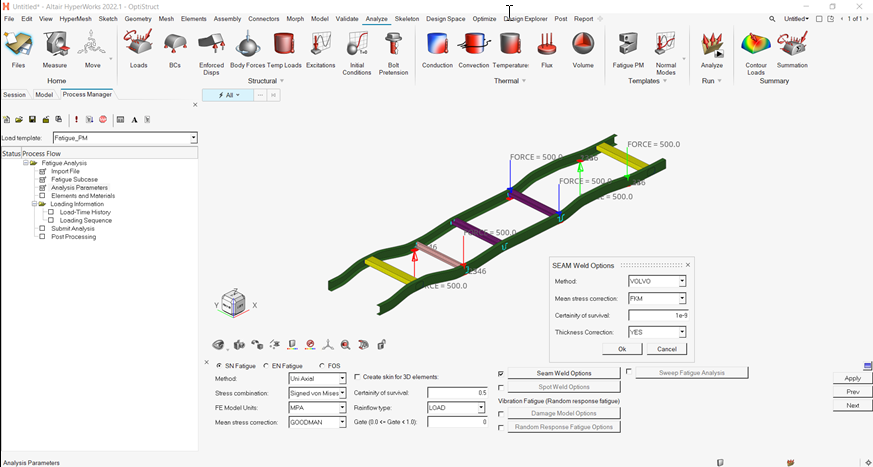

Apply Fatigue Analysis Parameters

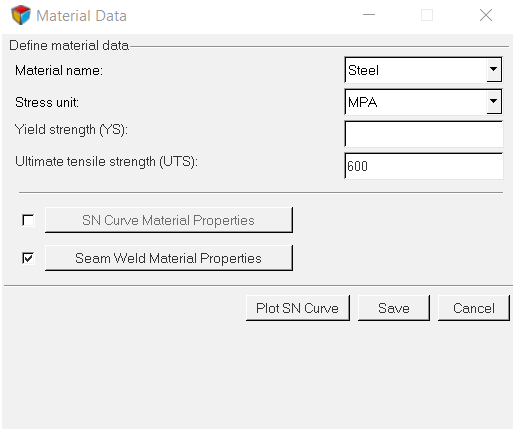

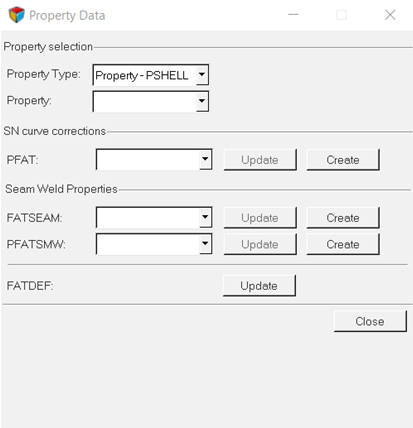

Add Fatigue Elements and Materials

Make sure the task Elements and Materials is selected in the Fatigue Analysis tree.

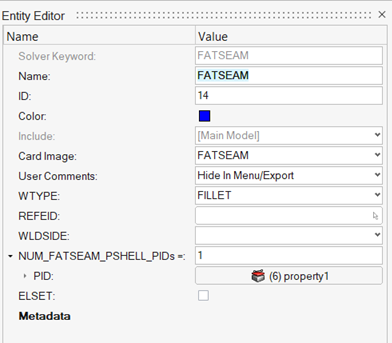

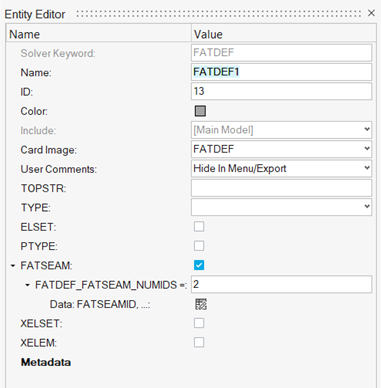

Define FATSEAM Load Collector

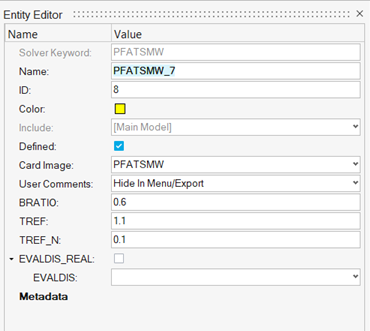

Define PFATSMW Property

This saves the current definitions and guides you to the next task Load-Time History of the Fatigue Analysis tree.

Update FATDEF Load Collector

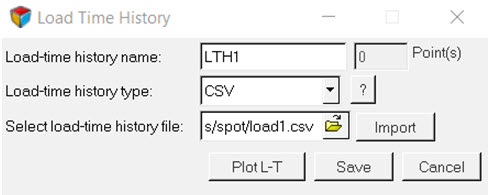

Apply Load-Time History

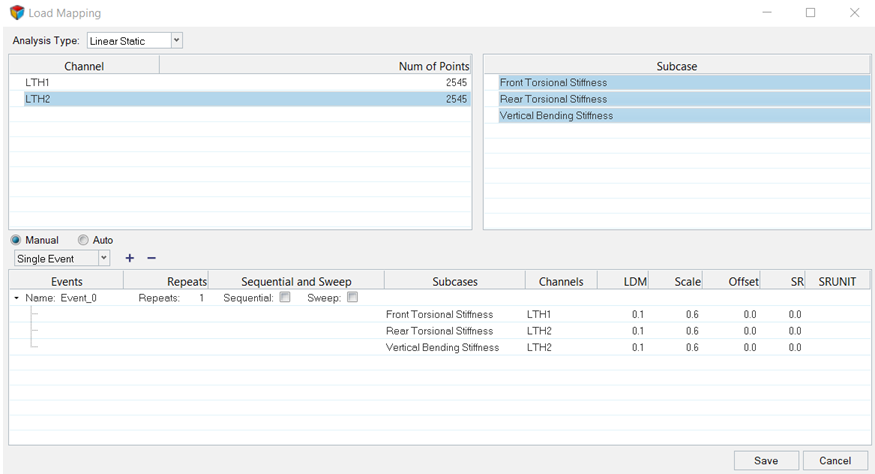

Load Sequences

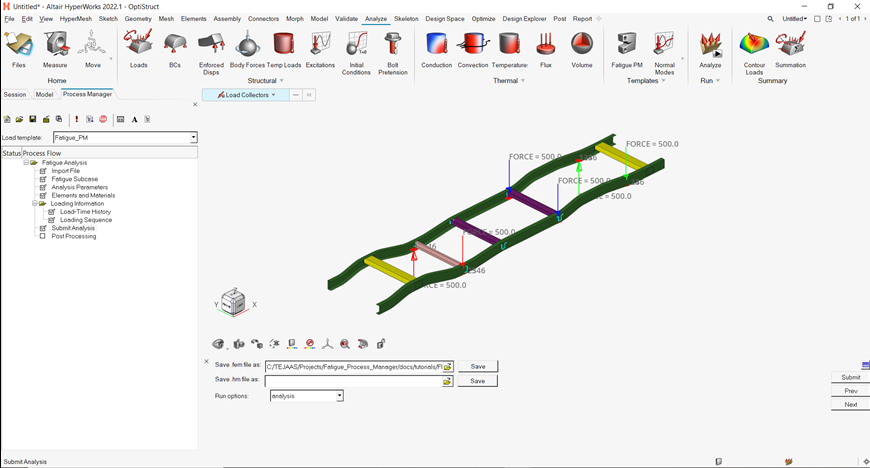

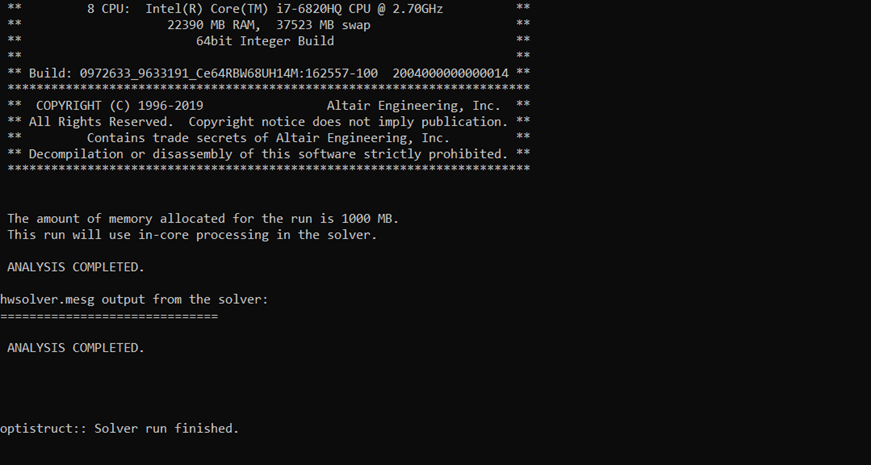

Submit the Job

Make sure the task Submit Analysis is selected in the Fatigue Analysis tree.

.

.