SS-T: 2040 Joints

Create joints in SimSolid.

- Purpose

- SimSolid performs meshless structural

analysis that works on full featured parts and assemblies, is tolerant of

geometric imperfections, and runs in seconds to minutes. In this tutorial,

you will do the following:

- Learn how to create joints - hinge and virtual pins.

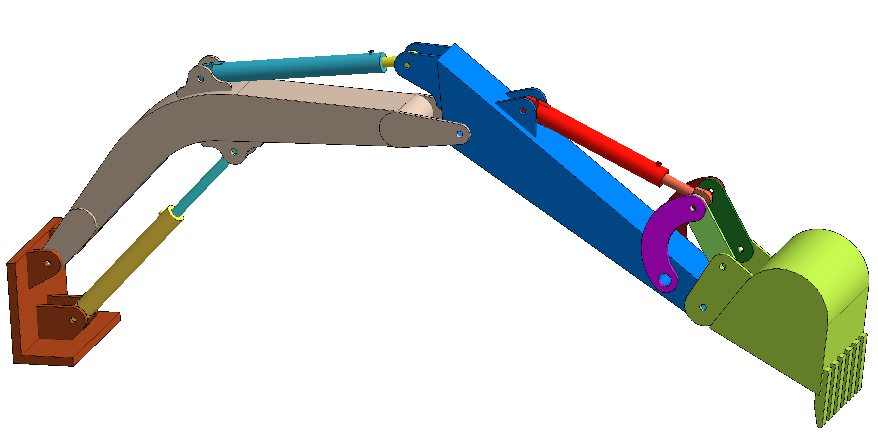

- Model Description

- The following model file is needed for this tutorial:

- Joints.ssp

Open Project

- Start a new SimSolid session.

-

On the main window toolbar, click Open Project

.

.

- In the Open project file dialog, choose Joints.ssp

- Click OK.

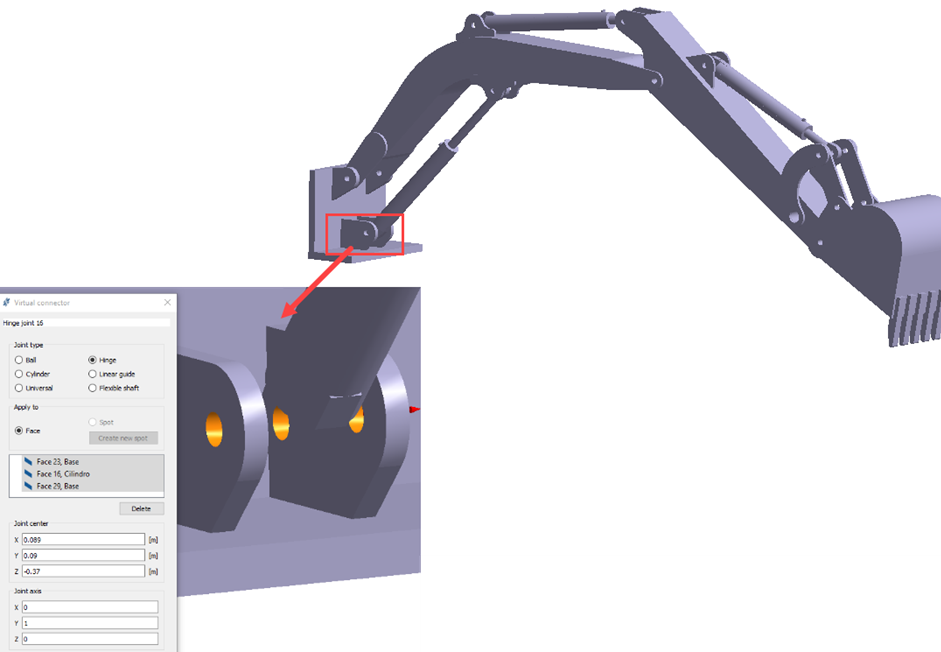

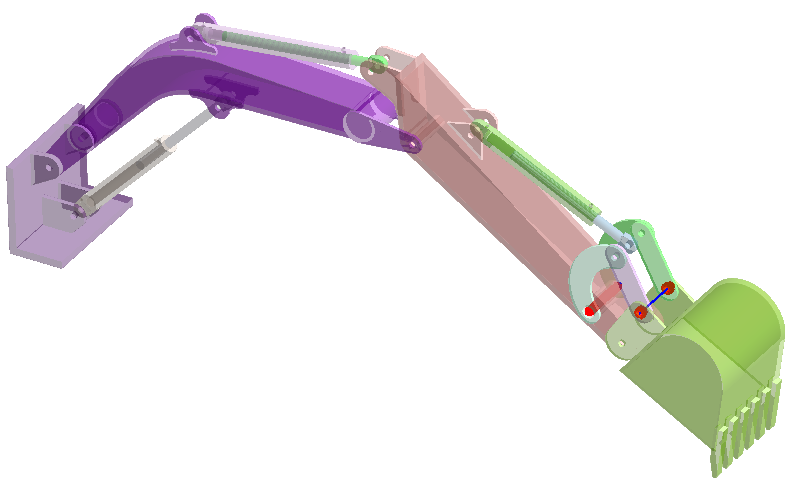

Create Hinge Joints

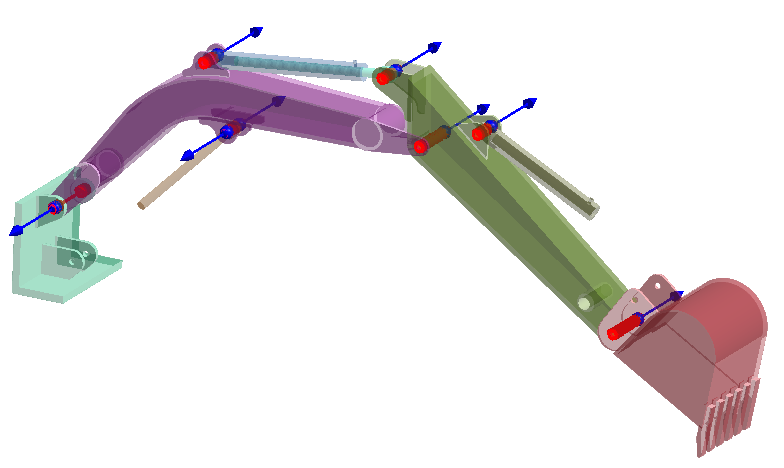

Create Sliding Contact

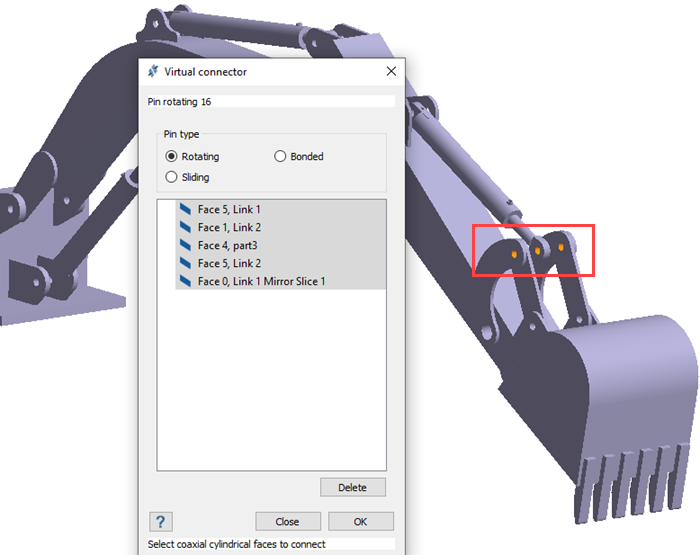

Create Virtual Pin

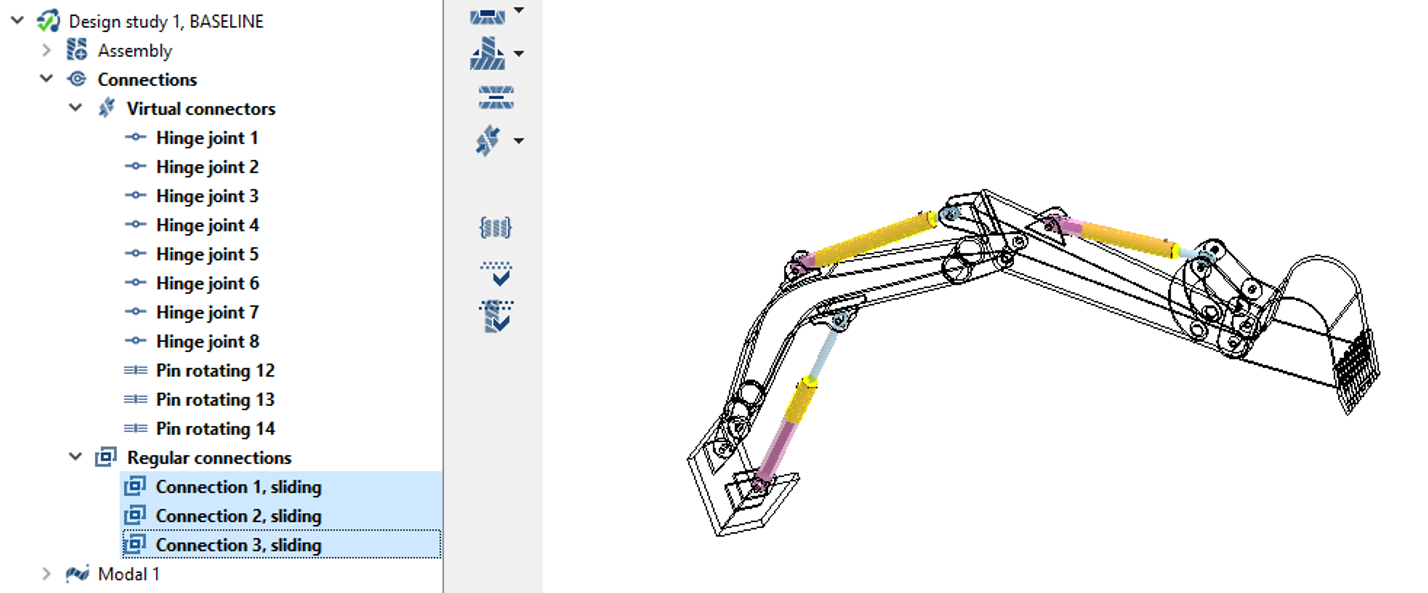

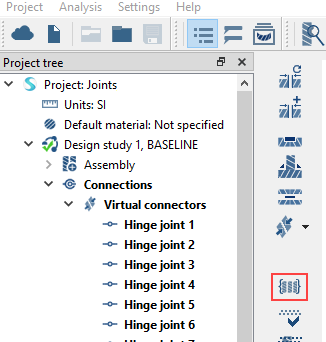

Review Connections

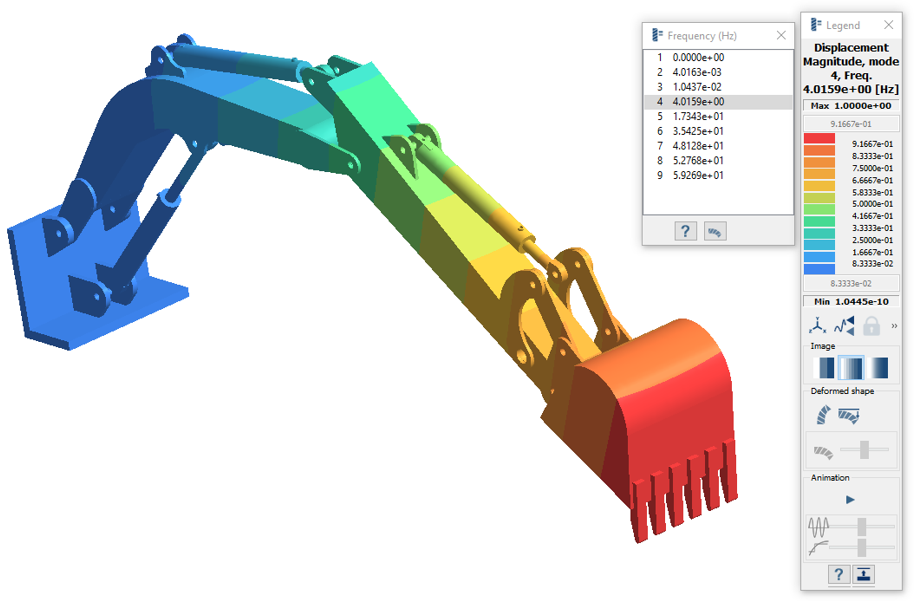

Run Analysis

- On the Project Tree, open the Analysis Workbench.

-

Click

(Solve).

(Solve).