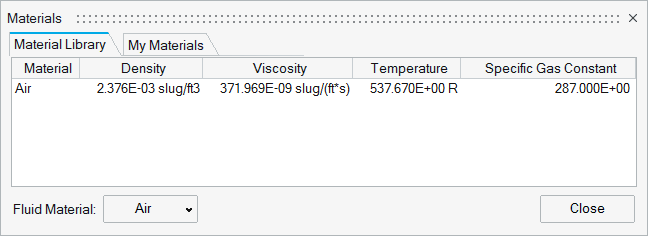

Define Fluid Materials

Use the Material tool to define a fluid material for the wind tunnel.

-

From the Setup ribbon, click the Material tool.

Figure 1. -

In the Materials dialog, define a fluid material.

- From the Material Library tab, select a predefined material. By default, air is defined.

- From the My Materials tab, define new materials by providing values for density, dynamic viscosity, temperature, and the specific gas constant.

-

From the Fluid Material drop-down menu, select a material for the wind

tunnel.

Figure 2.