Version: December 2010 Edition

List of Classification Parameters

Evaluation Distance

Reference distance to find the evaluation location from the weld element at

which the stress values are extracted.

Weld Width

Width of the weld material from the web wall. This parameter is ignored if

specifying the evaluation distance is done manually.

Safety Factor (Gmf)

Used in calculation of the corrected weld detail category.

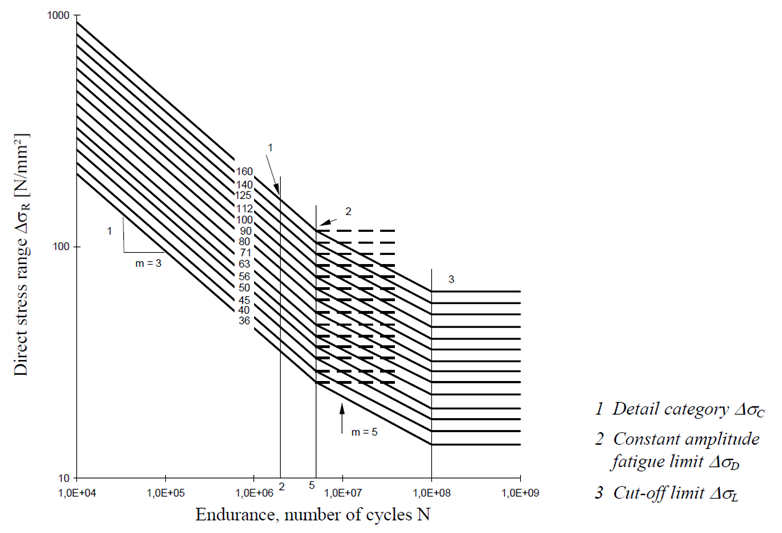

Fatigue Limit Slope - Normal Stress (Md)

Slope of the curve at the fatigue limit for normal stress components of

tensor. Refer to location 2 in the graph .

Fatigue Limit Slope - Shear Stress (Md)

Slope of the curve at the fatigue limit for shear stress components of

tensor. Refer to location 2 in the

graph .

Cutoff Limit Slope - Normal Stress (Ml)

Slope of the curve at the cutoff limit for normal stress components of

tensor. Refer to location 3 in the graph .

Cutoff Limit Slope - Shear Stress (Ml)

Slope of the curve at the cutoff limit for shear stress components of

tensor. Refer to location 3 in the graph .

Number of Cycles at Fatigue Limit (Nd)

Number of cycles in the S-N curve at the fatigue limit.

Number of Cycles at Cutoff Limit (Nd)

Number of cycles in the S-N curve at the cutoff limit.

Desired Cycles Detail From

Parameter that will show where HL-WC is reading

the desired number of cycles from.

Location Wise Parameters

Note: Where ‘X’ in the below parameters can be any evaluation location from 1-10.

Weld Detail Category - Transverse Location_X

Weld detail category from the image below that will be considered for the

calculation of fatigue and cutoff limits of the normal stress component in

the transverse direction (perpendicular to the axis of the weld) at

‘X’.

Weld Detail Category - Longitudinal Location_X

Weld detail category from the image below that will be considered for the

calculation of fatigue and cutoff limits of the normal stress component in

the longitudinal direction (parallel to the axis of the weld) at ‘X’.

Weld Detail Category - Shear Location_X

Weld detail category from the image below that will be considered for the

calculation of fatigue and cutoff limits of the shear stress component at

‘X’.

Material Yield - Location_X

Material yield value used for the static evaluation.

Figure 1.

Symbols

Weld detail category (Normal) -

Δ

σ

c

MathType@MTEF@5@5@+=

feaahqart1ev3aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaeuiLdqKaeq

4Wdm3aaSbaaSqaaiaadogaaeqaaaaa@3A30@

Weld detail category (Shear) -

Δ

τ

c

MathType@MTEF@5@5@+=

feaahqart1ev3aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaeuiLdqeeaa

aaaaaaa8qacqaHepaDpaWaaSbaaSqaaiaadogaaeqaaaaa@3A61@

Safety factor for strength -

γ

M

f

MathType@MTEF@5@5@+=

feaahqart1ev3aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaaeaaaaaaaaa8

qacqaHZoWzpaWaaSbaaSqaaiaad2eacaWGMbaabeaaaaa@39B2@

Static Assessment

The following process is followed for Static assessment:

Retrieve the six components of stress from the element at the evaluation

location.

Calculate the von Mises stress value using these stress components.

Retrieve the material yield value from the Points context.

Determine the static strength ratio: element von Mises stress / material

yield value.

Formulation

Stress Component Considered for Evaluation

Δ

σ

T

MathType@MTEF@5@5@+=

feaahqart1ev3aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaeuiLdqKaeq

4Wdm3aaSbaaSqaaiaadsfaaeqaaaaa@3A21@

Δ

σ

L

MathType@MTEF@5@5@+=

feaahqart1ev3aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaeuiLdqKaeq

4Wdm3aaSbaaSqaaiaadYeaaeqaaaaa@3A19@

Δ τ

MathType@MTEF@5@5@+=

feaahqart1ev3aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaeuiLdqeeaa

aaaaaaa8qacqaHepaDaaa@393E@

Corrected Weld Detail Category

Δ

σ

c

( C o r r e c t e d ) =

Δ

σ

c , B a s i c

γ

M f

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaeuiLdqKaeq

4Wdm3aaSbaaSqaaiaadogaaeqaaOGaaiikaiaadoeacaWGVbGaamOC

aiaadkhacaWGLbGaam4yaiaadshacaWGLbGaamizaiaacMcacqGH9a

qpdaWcaaqaaiabfs5aejabeo8aZnaaBaaaleaacaWGJbGaaiilaiaa

dkeacaWGHbGaam4CaiaadMgacaWGJbaabeaaaOqaaiabeo7aNnaaBa

aaleaacaWGnbGaamOzaaqabaaaaaaa@51F6@

Where:

Δ

σ

c

,

B

a

s

i

c

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaeuiLdqKaeq

4Wdm3aaSbaaSqaaiaadogacaGGSaGaamOqaiaadggacaWGZbGaamyA

aiaadogaaeqaaaaa@3F5E@

- Weld detail category before correction.

Note: The above formulas are for the normal component. Similar formulas

are applicable to other shear components as well.

Calculation of the Assessment Stress

In the case of Eurocode, stress range is used as assessment stress.

Δ σ ( S t r e s s R a n g e ) = (

σ

max

−

σ

min

)

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaeuiLdqKaeq

4WdmNaaiikaiaadofacaWG0bGaamOCaiaadwgacaWGZbGaam4Caiaa

ysW7caWGsbGaamyyaiaad6gacaWGNbGaamyzaiaacMcacqGH9aqpca

GGOaGaeq4Wdm3aaSbaaSqaaiGac2gacaGGHbGaaiiEaaqabaGccqGH

sislcqaHdpWCdaWgaaWcbaGaciyBaiaacMgacaGGUbaabeaakiaacM

caaaa@5311@

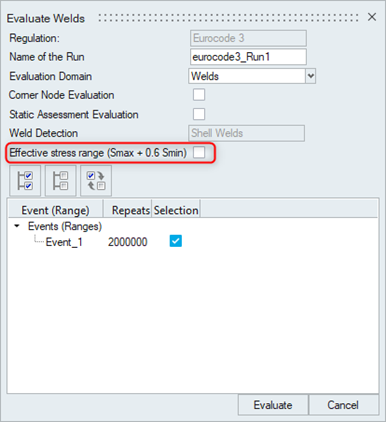

If effective stress range is enabled in evaluation to account for mean

stress influence on fatigue strength for non-welded and stress-relieved

welds, then stress range is calculated as shown below:

Δ σ ( E f f e c t i v e S t r e s s R a n g e ) = |

σ

max

| + 0.6 |

σ

min

|

MathType@MTEF@5@5@+=

feaahqart1ev3aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaeuiLdqKaeq

4WdmNaaiikaiaadweacaWGMbGaamOzaiaadwgacaWGJbGaamiDaiaa

dMgacaWG2bGaamyzaiaaysW7caWGtbGaamiDaiaadkhacaWGLbGaam

4CaiaadohacaaMe8UaamOuaiaadggacaWGUbGaam4zaiaadwgacaGG

PaGaeyypa0JaaGjbVlaacYhacaaMe8Uaeq4Wdm3aaSbaaSqaaiGac2

gacaGGHbGaaiiEaaqabaGccaaMe8UaaiiFaiabgUcaRiaaysW7caaI

WaGaaiOlaiaaiAdacaaMe8UaaiiFaiaaysW7cqaHdpWCdaWgaaWcba

GaciyBaiaacMgacaGGUbaabeaakiaaysW7caGG8baaaa@6C7C@

Figure 2.

Fatigue Limit Calculation

(

Δ

σ

D

MathType@MTEF@5@5@+=

feaahqart1ev3aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaeuiLdqKaeq

4Wdm3aaSbaaSqaaiaadseaaeqaaaaa@3A11@

For Normal Component:

Δ

σ

D

= Δ

σ

c

·

(

2 , 0 e + 6

N

D

)

( 1 /

m

D

)

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaeuiLdqKaeq

4Wdm3aaSbaaSqaaiaadseaaeqaaOGaeyypa0JaeuiLdqKaeq4Wdm3a

aSbaaSqaaiaadogaaeqaaOGaeS4JPF2aaeWaaeaadaWcaaqaaiaaik

dacaGGSaGaaGimaiaadwgacqGHRaWkcaaI2aaabaGaamOtamaaBaaa

leaacaWGebaabeaaaaaakiaawIcacaGLPaaadaahaaWcbeqaaiaacI

cacaaIXaGaai4laiaad2gadaWgaaadbaGaamiraaqabaWccaGGPaaa

aaaa@4EDF@

For Shear Component:

Δ

σ

D

=

∞

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaeuiLdqKaeq

4Wdm3aaSbaaSqaaiaadseaaeqaaOGaeyypa0JaeyOhIukaaa@3C95@

Where:

Δ

σ

c

MathType@MTEF@5@5@+=

feaahqart1ev3aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaeuiLdqKaeq

4Wdm3aaSbaaSqaaiaadogaaeqaaaaa@3A30@

- Corrected stress range

value

N

D

MathType@MTEF@5@5@+=

feaahqart1ev3aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaamOtamaaBa

aaleaacaWGebaabeaaaaa@37BB@

m

D

MathType@MTEF@5@5@+=

feaahqart1ev3aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaamyBamaaBa

aaleaacaWGebaabeaaaaa@37DA@

Cutoff Limit Calculation (

Δ

σ

L

MathType@MTEF@5@5@+=

feaahqart1ev3aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaeuiLdqKaeq

4Wdm3aaSbaaSqaaiaadYeaaeqaaaaa@3A19@

)

For Normal Component:

Δ

σ

L

= Δ

σ

D

·

(

N

D

N

L

)

( 1 /

m

L

)

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaeuiLdqKaeq

4Wdm3aaSbaaSqaaiaadYeaaeqaaOGaeyypa0JaeuiLdqKaeq4Wdm3a

aSbaaSqaaiaadseaaeqaaOGaeS4JPF2aaeWaaeaadaWcaaqaaiaad6

eadaWgaaWcbaGaamiraaqabaaakeaacaWGobWaaSbaaSqaaiaadYea

aeqaaaaaaOGaayjkaiaawMcaamaaCaaaleqabaGaaiikaiaaigdaca

GGVaGaamyBamaaBaaameaacaWGmbaabeaaliaacMcaaaaaaa@4BF8@

For Shear Component:

Δ

σ

L

= Δ

σ

c

·

(

2 , 0 e + 6

N

L

)

( 1 /

m

L

)

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaeuiLdqKaeq

4Wdm3aaSbaaSqaaiaadYeaaeqaaOGaeyypa0JaeuiLdqKaeq4Wdm3a

aSbaaSqaaiaadogaaeqaaOGaeS4JPF2aaeWaaeaadaWcaaqaaiaaik

dacaGGSaGaaGimaiaadwgacqGHRaWkcaaI2aaabaGaamOtamaaBaaa

leaacaWGmbaabeaaaaaakiaawIcacaGLPaaadaahaaWcbeqaaiaacI

cacaaIXaGaai4laiaad2gadaWgaaadbaGaamitaaqabaWccaGGPaaa

aaaa@4EF7@

Where:

Δ

σ

c

MathType@MTEF@5@5@+=

feaahqart1ev3aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaeuiLdqKaeq

4Wdm3aaSbaaSqaaiaadogaaeqaaaaa@3A30@

- Corrected stress range

value

Δ

σ

D

MathType@MTEF@5@5@+=

feaahqart1ev3aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaeuiLdqKaeq

4Wdm3aaSbaaSqaaiaadseaaeqaaaaa@3A11@

N

D

MathType@MTEF@5@5@+=

feaahqart1ev3aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaamOtamaaBa

aaleaacaWGebaabeaaaaa@37BB@

- Number of cycles at fatigue

limit

N

L

MathType@MTEF@5@5@+=

feaahqart1ev3aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaamOtamaaBa

aaleaacaWGmbaabeaaaaa@37C3@

m

L

MathType@MTEF@5@5@+=

feaahqart1ev3aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaamyBamaaBa

aaleaacaWGmbaabeaaaaa@37E2@

Permissible Number of Cycles

(

N

p e r m

MathType@MTEF@5@5@+=

feaahqart1ev3aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaamOtamaaBa

aaleaacaWGWbGaamyzaiaadkhacaWGTbaabeaaaaa@3ABA@

If Δ σ ≥ Δ

σ

D

N

p e r m

=

N

D

·

(

Δ σ

Δ

σ

D

)

(

−

m

D

)

If Δ

σ

D

> Δ σ ≥ Δ

σ

L

N

p e r m

=

N

L

·

(

Δ σ

Δ

σ

L

)

(

−

m

L

)

If Δ σ < Δ

σ

L

N

p e r m

= ∞

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGceaqabeaacaqGjb

GaaeOzaiaabccacqqHuoarcqaHdpWCcqGHLjYScqqHuoarcqaHdpWC

daWgaaWcbaGaamiraaqabaaakeaacaaMe8UaaGjbVlaaysW7caaMe8

UaaGjbVlaaysW7caaMe8UaaGjbVlaaysW7caaMe8UaaGjbVlaaysW7

caaMe8UaaGjbVlaaysW7caaMe8UaaGjbVlaaysW7caaMe8UaaGjbVl

aaysW7caaMe8UaaGjbVlaaysW7caaMe8UaaGjbVlaaysW7caaMe8Ua

aGjbVlaaysW7caaMe8UaaGjbVlaaysW7caaMe8UaaGjbVlaaysW7ca

aMe8UaaGjbVlaaysW7caaMe8UaaGjbVlaaysW7caaMe8UaaGjbVlaa

ysW7caaMe8UaaGjbVlaaysW7caaMe8UaaGjbVlaaysW7caaMe8UaaG

jbVlaaysW7caaMe8UaaGjbVlaaysW7caaMe8UaaGjbVlaaysW7caaM

e8UaaGjbVlaaysW7caaMe8UaaGjbVlaaysW7caaMe8UaaGjbVlaays

W7caaMe8UaaGjbVlaad6eadaWgaaWcbaGaamiCaiaadwgacaWGYbGa

amyBaaqabaGccqGH9aqpcaWGobWaaSbaaSqaaiaadseaaeqaaOGaeS

4JPF2aaeWaaeaadaWcaaqaaiabfs5aejabeo8aZbqaaiabfs5aejab

eo8aZnaaBaaaleaacaWGebaabeaaaaaakiaawIcacaGLPaaadaahaa

WcbeqaamaabmaabaGaeyOeI0IaamyBamaaBaaameaacaWGebaabeaa

aSGaayjkaiaawMcaaaaaaOqaaiaabMeacaqGMbGaaeiiaiabfs5aej

abeo8aZnaaBaaaleaacaWGebaabeaakiabg6da+iabfs5aejabeo8a

ZjabgwMiZkabfs5aejabeo8aZnaaBaaaleaacaWGmbaabeaaaOqaai

aaysW7caaMe8UaaGjbVlaaysW7caaMe8UaaGjbVlaaysW7caaMe8Ua

aGjbVlaaysW7caaMe8UaaGjbVlaaysW7caaMe8UaaGjbVlaaysW7ca

aMe8UaaGjbVlaaysW7caaMe8UaaGjbVlaaysW7caaMe8UaaGjbVlaa

ysW7caaMe8UaaGjbVlaaysW7caaMe8UaaGjbVlaaysW7caaMe8UaaG

jbVlaaysW7caaMe8UaaGjbVlaaysW7caaMe8UaaGjbVlaaysW7caaM

e8UaaGjbVlaaysW7caaMe8UaaGjbVlaaysW7caaMe8UaaGjbVlaays

W7caaMe8UaaGjbVlaaysW7caaMe8UaaGjbVlaaysW7caaMe8UaaGjb

VlaaysW7caaMe8UaaGjbVlaaysW7caaMe8UaaGjbVlaaysW7caaMe8

UaaGjbVlaaysW7caaMe8UaaGjbVlaaysW7caaMe8UaamOtamaaBaaa

leaacaWGWbGaamyzaiaadkhacaWGTbaabeaakiabg2da9iaad6eada

WgaaWcbaGaamitaaqabaGccqWIpM+zdaqadaqaamaalaaabaGaeuiL

dqKaeq4WdmhabaGaeuiLdqKaeq4Wdm3aaSbaaSqaaiaadYeaaeqaaa

aaaOGaayjkaiaawMcaamaaCaaaleqabaWaaeWaaeaacqGHsislcaWG

TbWaaSbaaWqaaiaadYeaaeqaaaWccaGLOaGaayzkaaaaaaGcbaGaae

ysaiaabAgacaqGGaGaeuiLdqKaeq4WdmNaeyipaWJaeuiLdqKaeq4W

dm3aaSbaaSqaaiaadYeaaeqaaaGcbaGaaGjbVlaaysW7caaMe8UaaG

jbVlaaysW7caaMe8UaaGjbVlaaysW7caaMe8UaaGjbVlaaysW7caaM

e8UaaGjbVlaaysW7caaMe8UaaGjbVlaaysW7caaMe8UaaGjbVlaays

W7caaMe8UaaGjbVlaaysW7caaMe8UaaGjbVlaaysW7caaMe8UaaGjb

VlaaysW7caaMe8UaaGjbVlaaysW7caaMe8UaaGjbVlaaysW7caaMe8

UaaGjbVlaaysW7caaMe8UaaGjbVlaaysW7caaMe8UaaGjbVlaaysW7

caaMe8UaaGjbVlaaysW7caaMe8UaaGjbVlaaysW7caaMe8UaaGjbVl

aaysW7caaMe8UaaGjbVlaaysW7caaMe8UaaGjbVlaaysW7caaMe8Ua

aGjbVlaaysW7caaMe8UaaGjbVlaaysW7caaMe8UaaGjbVlaaysW7ca

aMe8UaaGjbVlaaysW7caWGobWaaSbaaSqaaiaadchacaWGLbGaamOC

aiaad2gaaeqaaOGaeyypa0JaeyOhIukaaaa@DDC3@

Damage Calculation

D

=

N

N

p

e

r

m

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaamiraiabg2

da9maalaaabaGaamOtaaqaaiaad6eadaWgaaWcbaGaamiCaiaadwga

caWGYbGaamyBaaqabaaaaaaa@3D6F@

Where:

N

MathType@MTEF@5@5@+=

feaahqart1ev3aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaamOtaaaa@36C6@

Resultant Damage Calculation (D)

D

=

D

δ

,

y

+

D

δ

,

x

y

MathType@MTEF@5@5@+=

feaahqart1ev3aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVCI8FfYJH8YrFfeuY=Hhbbf9v8qqaqFr0xc9pk0xbb

a9q8WqFfeaY=biLkVcLq=JHqpepeea0=as0Fb9pgeaYRXxe9vr0=vr

0=vqpWqaaeaabiGaciaacaqabeaadaqaaqaaaOqaaabaaaaaaaaape

Gaamiraiabg2da9iaadseapaWaa0baaSqaa8qacqaH0oazcaGGSaGa

amyEaaWdaeaapeGaaG4maaaakiabgUcaRiaadseapaWaa0baaSqaa8

qacqaH0oazcaGGSaGaamiEaiaadMhaa8aabaWdbiaaiwdaaaaaaa@444B@

Where:

D

δ

,

y

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaamiramaaBa

aaleaacqaH0oazcaGGSaGaamyEaaqabaaaaa@3A3E@

- Damage in transverse direction (perpendicular to the

axis of the weld)

D

τ

,

x

y

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaamiramaaBa

aaleaacqaHepaDcaGGSaGaamiEaiaadMhaaeqaaaaa@3B5B@

- Damage in the shear direction

Calculation of Accumulated Damage

For the corresponding damage components:

D

δ , x , a c c

=

∑

D

x , i

D

δ , y , a c c

=

∑

D

y , i

D

τ , x y , a c c

=

∑

D

x y , i

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGceaqabeaacaWGeb

WaaSbaaSqaaiabes7aKjaacYcacaWG4bGaaiilaiaadggacaWGJbGa

am4yaaqabaGccqGH9aqpdaaeabqaaiaadseadaWgaaWcbaGaamiEai

aacYcacaWGPbaabeaaaeqabeqdcqGHris5aaGcbaGaamiramaaBaaa

leaacqaH0oazcaGGSaGaamyEaiaacYcacaWGHbGaam4yaiaadogaae

qaaOGaeyypa0ZaaabqaeaacaWGebWaaSbaaSqaaiaadMhacaGGSaGa

amyAaaqabaaabeqab0GaeyyeIuoaaOqaaiaadseadaWgaaWcbaGaeq

iXdqNaaiilaiaadIhacaWG5bGaaiilaiaadggacaWGJbGaam4yaaqa

baGccqGH9aqpdaaeabqaaiaadseadaWgaaWcbaGaamiEaiaadMhaca

GGSaGaamyAaaqabaaabeqab0GaeyyeIuoaaaaa@6332@

For resultant accumulated damage calculation:

D =

D

δ , y , a c c

+

D

δ , x y , a c c

MathType@MTEF@5@5@+=

feaahqart1ev3aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVCI8FfYJH8YrFfeuY=Hhbbf9v8qqaqFr0xc9pk0xbb

a9q8WqFfeaY=biLkVcLq=JHqpepeea0=as0Fb9pgeaYRXxe9vr0=vr

0=vqpWqaaeaabiGaciaacaqabeaadaqaaqaaaOqaaabaaaaaaaaape

Gaamiraiabg2da9iaadseapaWaa0baaSqaa8qacqaH0oazcaGGSaGa

amyEaiaacYcacaWGHbGaam4yaiaadogaa8aabaWdbiaaiodaaaGccq

GHRaWkcaWGebWdamaaDaaaleaapeGaeqiTdqMaaiilaiaadIhacaWG

5bGaaiilaiaadggacaWGJbGaam4yaaWdaeaapeGaaGynaaaaaaa@4B17@

Note: DIN is the copyright owner for EN 1999-1-3:2011-11 (November

2011). Permission to use and reproduce information contained in the

Eurocode 3 standards was granted by DIN.