Composites

New Features

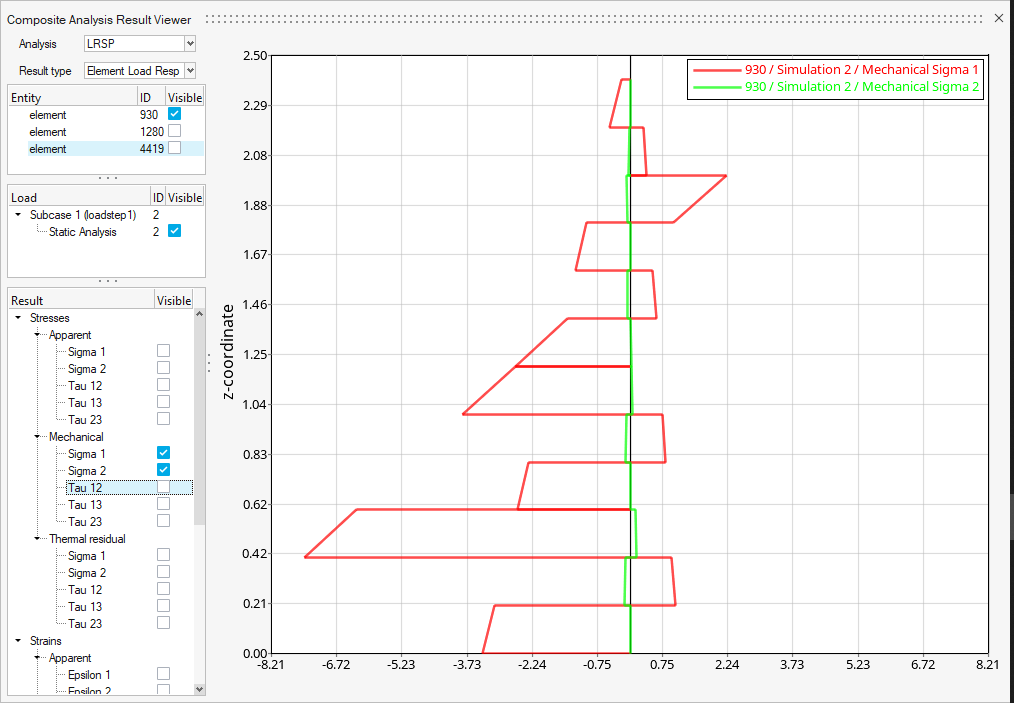

- Load Response Through Thickness Plots Support Multi-Selection

- This allows for easy comparison of different stresses, load cases, or

elements/laminates.

Figure 1.

Enhancements

- Injection Mold Mapping

- Abaqus solver support for injection mold mapping on shell elements.

- OptiStruct and Nastran Profiles

- MAT2 material card is supported for material engineering constants analysis.

- Constants Table and Plot Results

- The number of elements for engineering constants table and plot results is now limited to 1000.

- Laminate Data Section Harmonized

- The laminate data section in all laminate analyses has been harmonized.

Known Issues

- There are performance issues on ply stacking in larger models.

- There are performance issues in models with many laminates.

- Derived load cases are not yet supported in composite stress toolbox.

- Load response contouring does not fully support symmetric laminates. While element contour already takes symmetry into account fully, the ply wise result selection is still lacking the symmetric layers.

- Contouring load response for PCOMPG relies on layer index instead of global ply ID.

- Error messaging for analysis of elements with PSHELL property lacks details for some corner cases.

Resolved Issues

- Performance improvements have been made for ply visualization in large models.

- The Material Orientation tool now creates non orthogonal systems on certain models with "Curve" method.

- Segmentation fault when reviewing ply with detailed thickness and layers on, then turning detailed thickness off has been resolved.

- Solid ply shape realization data not being output to table has been resolved.

- Ply sets empty after Ansys property absorb has been resolved.

- Elements are now highlighted when selected for detailed results from composite stress toolbox contour results.

- The *compositeanalysis command theta option now supports real values instead of integer to allow rotations lower than one degree.

- Ply realization with kinematic drape method (applying a drape table’s information to a different mesh or ply) now assigns thickness information correctly and shows corresponding status message.