Find Welds Between Primary and Adjacent Parts

Find welds on the edges between a single primary part and a group of adjacent parts.

-

On the Connections workbench toolbar, click

(Create seam weld).

(Create seam weld).

- In the dialog, define the Section size (the length measured from the toe to the root of the weld).

-

Define the Minimum length.

Note: Any geometric edges found that are less than the minimum weld length will not receive a weld.

- Optional:

Activate the Intermittent weld checkbox to specify

intermittent welds.

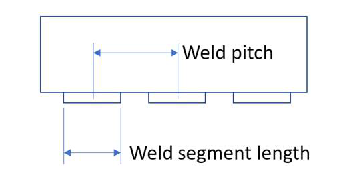

Note: Two parameters, weld pitch and weld segment length, are required for intermittent welds. the pitch must be greater than the segment length.

Figure 1. - Click the Primary weld tab in the Create seam welds dialog.

-

Select primary and secondary part(s)

- Verify the Primary part radio button is selected.

- Click on a part in the modeling window to select a primary part.

- Activate the Secondary part(s) of primary part radio button.

- Click on parts in the modeling window to choose the secondary part(s).

Note: It is possible to create a connection between multiple faces on a single part. To do so, select the same part in both the master and mate part fields. -

Click the Find welds button.

All welds found will be shown in the Welds found list. Each weld you select will be highlighted on the model.

- Optional: Use the Delete button to remove unwanted welds from the Welds found list.

- Click OK.