Limited Slip Differential (LSD)

LSD in MotionView Vehicle Libraries

In MotionView’s Car/Small truck and Heavy truck library, a viscous coupling is used between the left-right drive shafts to model the slip limit.

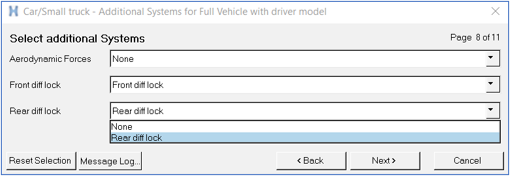

Figure 1. Differential lock selection for a 4wd configuration

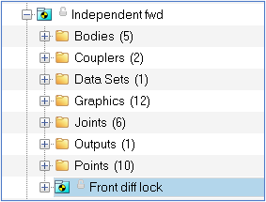

Figure 2. Differential lock within the Drive system

LSD Model

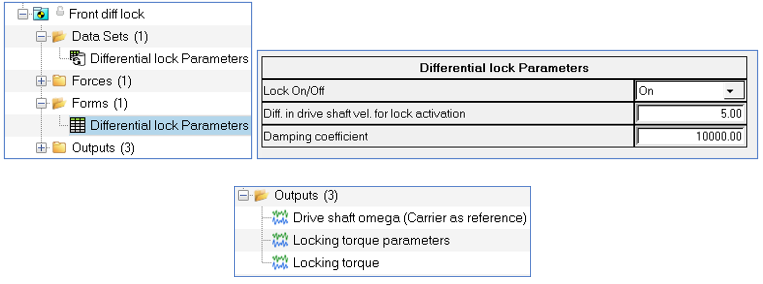

- A damping coefficient (DAMP_COEFF)

- Delta of rotational speeds of the shafts (OMEGA_DIFFERENCE)

- Desired allowable difference between shafts’ rotational speeds (ALLOWABLE_SPEED_DIFFERENCE)

- A numerical switch (1, 0) that is used to switch On/Off the locking torque (LOCK_STATE)

T = LOCK_STATE * DAMPING_COEFF * (| OMEGA_LEFT – OMEGA_RIGHT |)

To allow for a smooth transition while engaging the lock, a STEP() function is used in the above expression:

T = LOCK_STATE * STEP( OMEGA_DIFFERENCE, ALLOWABLE_SPEED_DIFFERENCE, ALLOWABLE_SPEED_DIFFERENCE + 0.1, DAMP_COEFF * OMEGA_DIFFERENCE )

The torque acts between the Left and Right halves of the drive shaft.

Interface

Figure 3. Interface for editing parameters and Outputs