Nonlinear Structural Solutions

Phone Drop Simulation

This simulation is of an accidental drop of a cell/mobile phone.

Use-Case

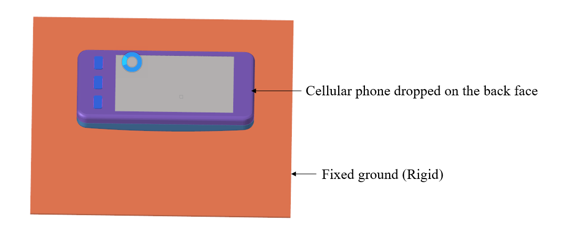

Here a back face drop of the phone was considered when falling from height with a speed of 5 ms-1.

How many times have you accidentally dropped your cell/mobile phone on the floor?

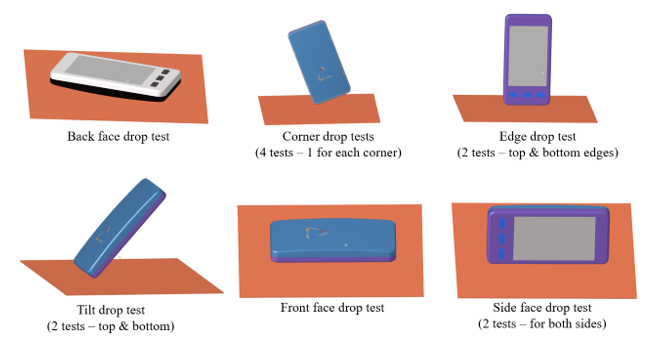

The most common failure mode of cell/mobile phones is the impact, due to an accidental drop. So, the manufacturers aim to develop products that are impact-resistant and can survive the drop test from a specific height where the cell/mobile phones are expected to continue functioning after suffering a drop with no or only minor damage. In general, phones are analyzed in a drop test using 12 load cases (Figure 1).

Figure 1. Analysis Orientations

Model Files

FEA Model Description

A drop test analysis of the phone was conducted, considering various parts of the phone including buttons, camera, Printed Circuit Board (PCB), glass, touch-sensors, battery, etc. Nonlinear contact and nonlinear materials for these parts were assigned.

Figure 2. Back Face Drop Test

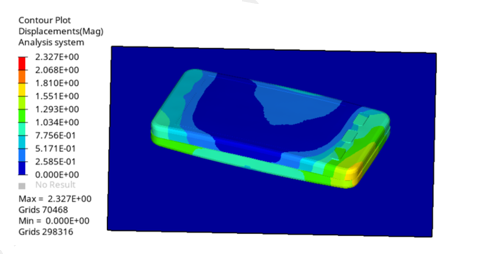

Results

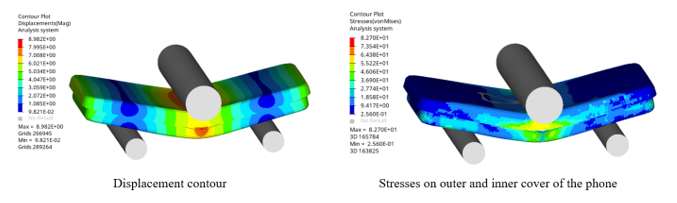

Figure 3. Displacement Contour

3-Point Bending Simulation

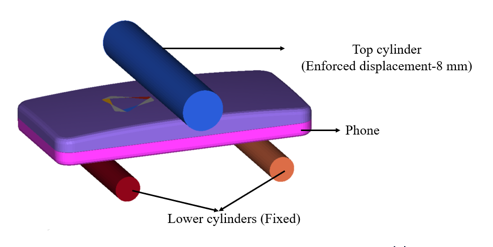

The force versus bend angle is analyzed when at the center of the phone force is applied to the back cover of the phone.

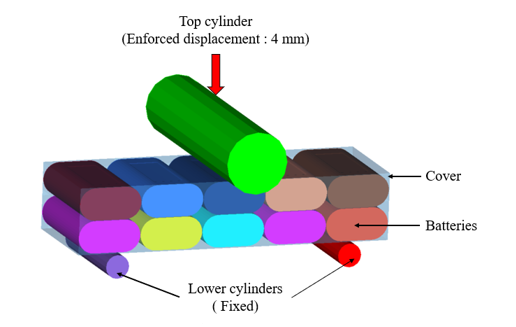

In this analysis, the phone is kept on two cylinders which are fixed as shown in and then force is applied on the phone in the middle. Tests are usually performed on both front and backside of the phone.

Use-Case

Cellular phones are generally made of aluminum for enabling a lightweight construction and for the ease of manufacturability. Phones have become increasingly slimmer and lightweight, reducing their structural properties. Metals commonly used in construction such as aluminium are flexible by nature and this exuberates the problem of bending.

When the phone is kept in the back pocket and someone who sits with the phone in the pocket, chances are high of the phone bending. This phenomenon of bending can be measured with a 3-point bending test, which is performed with the normal force that is generated when a person presses the back pocket is approximately 300N– 400N.

Model Files

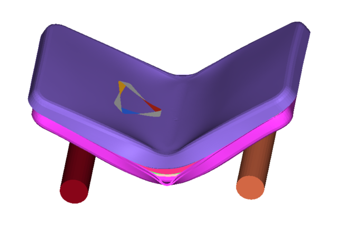

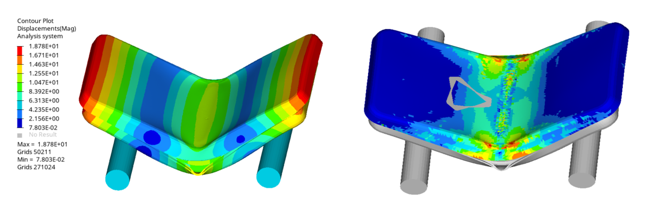

FEA Model Description

Figure 4. FEA Model

Results

Figure 5. Displacement and Stress Contour Plot

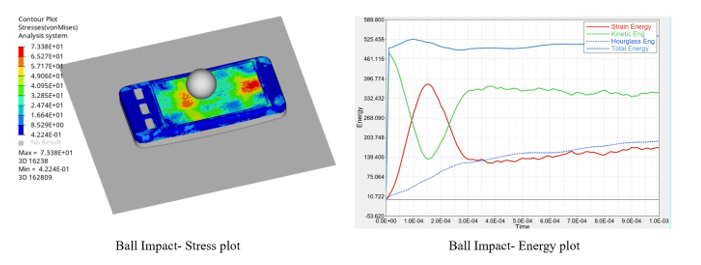

Ball Impact on Cell Phone Analysis

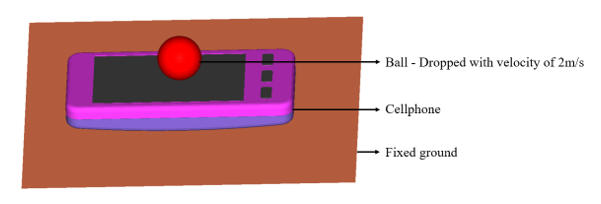

The stresses and strains on the front face of the phone are analyzed as a ball is dropped on the front face.

Use-Case

When a phone is laying on a table and a bunch of keys or a bag is dropped on the phone accidentally, what would happen to the phone? Either the screen will break or there will be some scratches on the phone. A ball impact test is performed to check for the hardness, scratch resistivity and the penetration resistance of the phone.

Model Files

FEA Model Description

Figure 6. FEA Model

Results

Figure 7. Stress Plot and Energy Plot

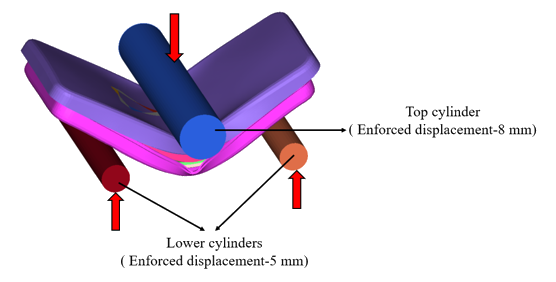

Foldable Phone Analysis

The bendability of the phone is analyzed. A 3-point bending analysis is conducted on this foldable phone test to analyze the stresses and strains on the phone.

Use-Case

Figure 8. Foldable Phone. Motorola Razr V4

Model Files

FEA Model Description

- Enforced displacement of 8 mm is applied on the pressing cylinder keeping the lower cylinders fixed.

- Enforced displacement of 5 mm upwards is applied, thus getting results of the folding analysis.

Figure 9. FEA Model

Figure 10. Deformed Structure

Results

Figure 11. Displacement Results for Both Sides of the Folding Phone

Washing Machine Simulation: Torsional and Pressure

Here a simulation of the washing machine in one of the most dangerous situations, rotating at high speed, with a completely unbalanced load. The model rotation is given to the drum and pressure is applied. Stresses, strain and directional displacement are analyzed in this analysis.

Use-Case

Washing machines are commonly used in almost every home worldwide. These appliances make it easy to clean clothes by going through the wash/agitation cycle, rinse cycle and spin cycle. The performance of these machines is based on the rotation of the clothes inside a drum, while they are mixed with water and cleaning powder or soap. It is natural that a load of clothes, when they are soaked in water, can create big reaction forces in the drum because of the weight when they are rotating. This situation makes it very important to calculate accurately the mechanical characteristics of the drum.

A lot of washing machine manufacturers conduct various tests for different applications of washing machines, such as water temperature, pressure applied, allowable size of the load, etc.

Model Files

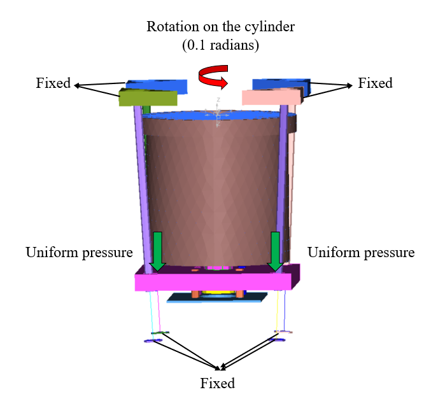

FEA Model Description

Figure 12. FEA Model

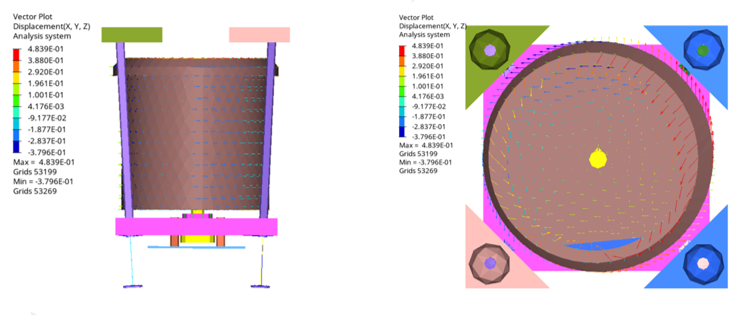

Results

Figure 13. Displacement Plot. side and top views

Battery Pack Bending Simulation

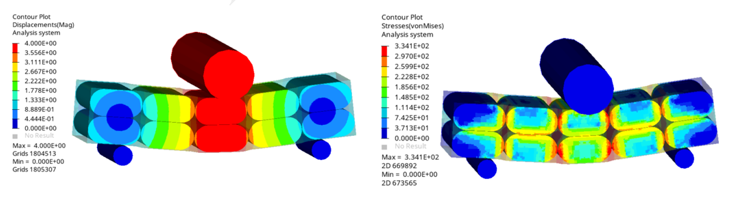

The structural performance of a battery pack is evaluated using a 3-point bending test.

Use-Case

Battery packs are a set of batteries arranged in a series or parallel, to provide the required power to electronic devices. The application of such battery packs is wide-ranging from phones to lawn mowers, automobiles to agricultural applications. The cells in the battery pack are the smallest energy resource entity that needs to satisfy a number of critical tests to fulfill the requirements for better characterization of battery cell components. Battery packs of an automobile can be bent because of accidents or overheating, which is very hazardous, as it can lead to a fire. The lithium-ion battery packs are not bendable or twistable, so repeated bending of such batteries can deteriorate the charging and discharging cycle, as well as the life of the battery.

Model Files

FEA Model Description

Figure 14. FEA Model

Results

Figure 15. Displacement and Stress Plots