/FAIL/SYAZWAN

Block Format Keyword This simplified failure criterion is based on a fracture surface with linear damage accumulation. It also provides the initialization of damage value using strain histories with linear strain path assumptions.

Format

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| /FAIL/SYAZWAN/mat_ID/unit_ID | |||||||||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| C1 | C2 | C3 | C4 | C5 | |||||

| C6 | |||||||||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| Dinit | Dsf | Dmax | |||||||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| Inst | Iform | Nvalue | Softexp | ||||||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| fct_IDEl | El_ref | Fscale_El | |||||||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| fail_ID |

Definition

| Field | Contents | SI Unit Example |

|---|---|---|

| mat_ID | Material identifier. (Integer, maximum 10 digits) |

|

| unit_ID | (Optional) Unit

identifier. (Integer, maximum 10 digits) |

|

Card input format flag. 3

(Integer) |

||

| Minimum plastic strain at

failure. Default = 0.0 (Real) |

||

| C1 | First constant for failure

surface. (Real) |

|

| C2 | Second constant for failure

surface. (Real) |

|

| C3 | Third constant for failure

surface. (Real) |

|

| C4 | Fourth constant for failure

surface. (Real) |

|

| C5 | Fifth constant for failure

surface. (Real) |

|

| C6 | Sixth constant for failure

surface. (Real) |

|

| Plastic strain at failure for

uniaxial compression. (Real) |

||

| Plastic strain at failure for

shearing. (Real) |

||

| Plastic strain at failure for

uniaxial tension. (Real) |

||

| Plastic strain at failure for plane

strain. (Real) |

||

| Plastic strain at failure for

biaxial tension. (Real) |

||

| Dinit | Damage value initialization from

strain tensors flag.

(Integer) |

|

| Dsf | Damage initialization scale

factor. Default = 1.0 (Real) |

|

| Dmax | Damage initialization maximum

value. Default = 1.0 (Real) |

|

| Inst | Necking instability flag.

(Integer) |

|

| Iform | Necking instability formulation flag.

(Integer) |

|

| Nvalue | The N-value derived from Hollomon’s

Law. Default = 0.25 (Real) |

|

| Softexp | Stress softening

exponent. Default = 1.0 (Real) |

|

| fct_IDEl | Element size factor function

identifier. (Integer) |

|

| El_ref | Reference element size. Default = 1.0 (Real) |

|

| Fscale_El | Element size factor function scale

factor. Default = 1.0 |

|

| fail_ID | (Optional) Failure criteria

identifier. (Integer, maximum 10 digits) |

Example

/FAIL/SYAZWAN/1

# ICARD EPFMIN

2 0.0

# EPF_COMP EPF_SHEAR EPF_TENS EPF_PLSTRN EPF_BIAX

3.009 0.98 0.7 0.42 0.56

# DAM_INIT DAM_SF DAM_MAX

# INST IFORM N_VAL SOFTEXP

1 2 0.25 1.2

# FCT_EL EL_REF ELSCAL

/FAIL/SYAZWAN/1

# ICARD EPFMIN

1 0.0

# C1 C2 C3 C4 C5

0.65 -3.2234 -0.08 3.9031 0.2652

# C6

0.5266

# DAM_INIT DAM_SF DAM_MAX

# INST IFORM N_VAL SOFTEXP

1 1 0.27 1.2

# FCT_EL EL_REF ELSCALComments

- It is highly recommended to set the value of in /PROP/SHELL to 1. This will allow accurate calculation of the principal strain ratio .

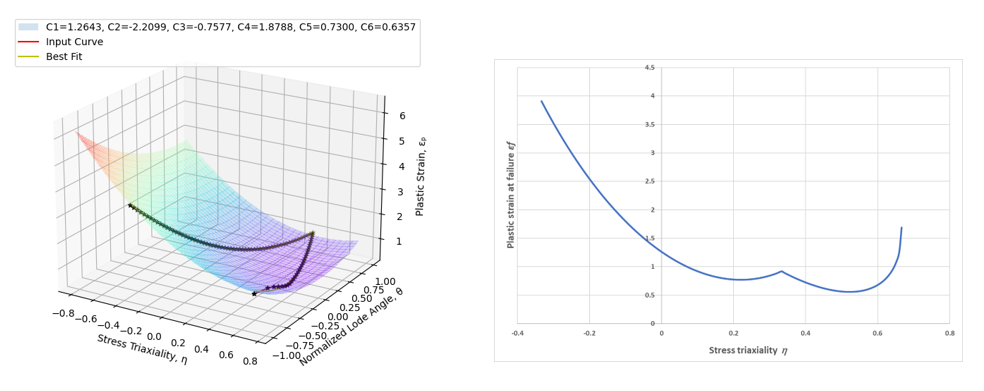

- The value of C1, C2, C3, C4, C5, and C6 is based on:

(1) Where,- Plastic strain at failure.

- Stress triaxiality with

- Normalized Lode angle

Where, is the von Mises stress.

Figure 1 shows the example of curve fit of plane stress failure curve into failure surface criteria.

Figure 1. Example of Syazwan failure criterion fit - Two different parameter

input card formats are available for /FAIL/SYAZWAN

depending on the value of

.

- If = 1: you must directly input the Ci parameters

- If

= 2: you can

specify some plastic strain at failure for several commonly tested

loading conditions: uniaxial compression

, shearing

, uniaxial tension

, plane strain

and biaxial tension

. In that case, the

Ci parameter

will be automatically computed by solving the set of equations

below:

(2)

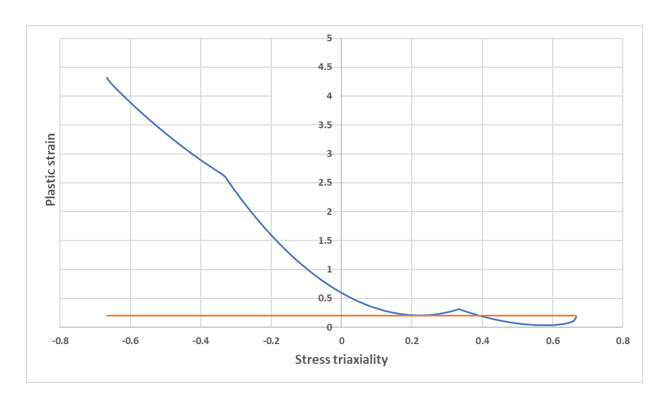

Note: The last equation imposes that the plane strain condition corresponds to a local minimum of the failure criterion. - In some cases, the criterion may have negative or very low values

for some loading conditions. In that case, it will be bounded by the minimum

plastic strain at failure parameter

that must be positive or null (by default =

0.0). All values under

are then ignored. Figure 2 shows an example with a minimum value (orange curve) of 0.2.

Figure 2. Failure criterion (blue curve) bounded by plastic strain at failure minimum value. (orange curve) of 0.2 - The damage variable evolution is computed incrementally

as:

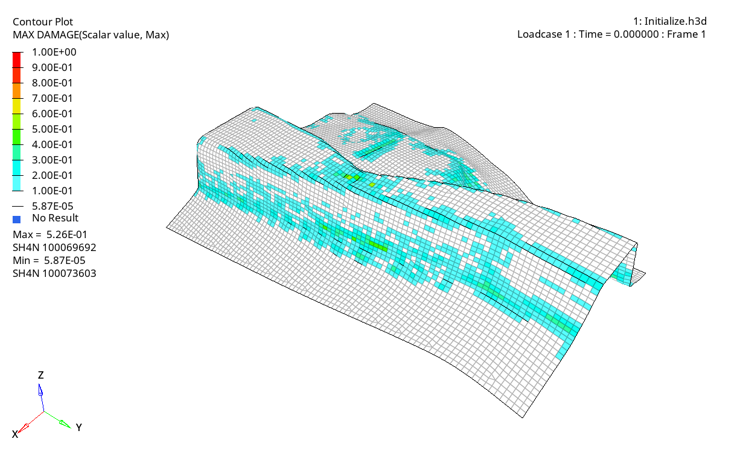

(3) - You may want to realize a simulation starting from existing total

and plastic strains fields (after a previous forming simulation for

instance). In the case where the failure criterion is not computed during

the first simulation, it is possible to estimate a damage field from the

total strain tensor and the plastic strain values obtained at the end of the

first simulation (using .sta files). If the

Dinit flag is set to

1, the damage field will be computed if the plastic

strain ≠ 0. /INISHE/STRA_F,

/INISHE/STRA_F, /INISHE/EPSP_F and

/INISH3/EPSP_F must be present in the keywords of the

status file. The initial stress tensors are not incorporated into the

simulation model; thus, the stress triaxiality is derived

using:

(4) The value can be recovered from the stress triaxiality value using the first root of Equation 4:(5) Then, an initial damage value can be estimated as:(6) Figure 3 shows an example of initialized damage field in one-step after a forming simulation performed without failure criterion computation. Damage field is then deduced using the plastic strain and the strain tensor as presented above.

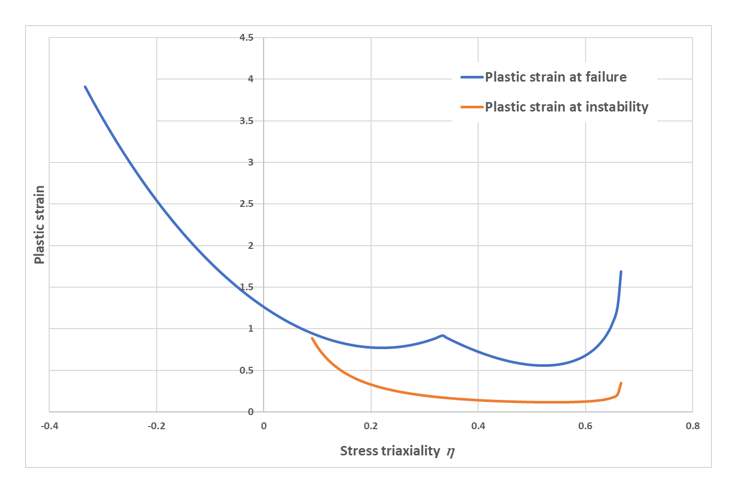

Figure 3. Example of damage field “one-step” initialization after a forming simulation - A controlled necking instability can be used if the flag

Inst is set to 1. To trigger this

instability, a criterion variable denoted

is computed based on the

Nvalue specified by

you, using:

(7) Where, ratio between the minor principal and major principal stress computed from using:(8) You can then compute an effective plastic strain at necking instability:(9) The parameter Nvalue is the value of the instability plastic strain taken in uniaxial tension (for which and ). You can then use the relation linking and the stress triaxiality described above to plot the instability strain evolution.

Using the instability plastic strain, an instability criterion variable denoted is either computed:- Incrementally (if Iform = 1)

to take into account the loading history

(10) - Directly (if Iform = 2) to

ignore the loading path history

(11)

If the criterion is reached ( ), the instant value of the damage variable is saved in the value that becomes an element history variable. The necking instability can then be triggered by a stress softening whose equation is:(12) Where,- Damaged stress tensor.

- Undamaged effective stress tensor.

- Critical damage value that triggers stress softening.

- Exponent parameter.

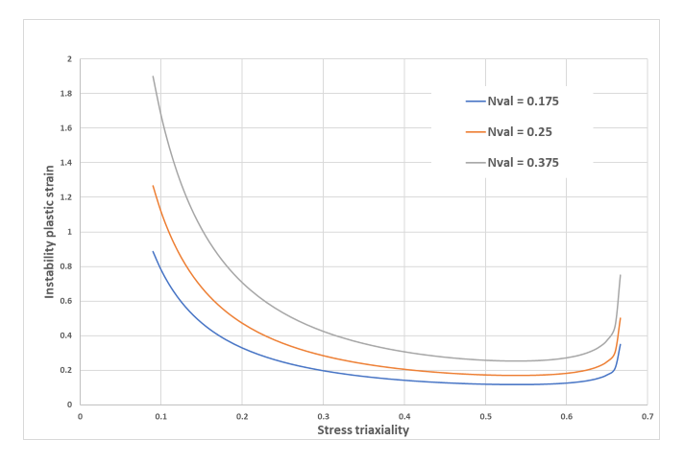

For visualization purposes, the instability curve ( versus ) can be obtained from all the equations above. For instance, if the Nvalue is set to 0.175, the following curve (Figure 4) is obtained.

Figure 4. Example of instability curve (orange) and its position with respect to failure criterion (blue)The effect of instability curve is restricted to positive stress triaxiality (as necking only occurs in tension) and only has an effect when it is under the failure criterion curve.

Figure 5 shows several instability curves obtained with different Nvalue parameter values.

Figure 5. Instability curves obtained with different Nvalue parameters - Incrementally (if Iform = 1)

to take into account the loading history

- Element size scaling can be used to regularize the failure and

ensure to obtain an almost constant fracture energy dissipated with

different mesh sizes. This element size dependency is introduced by

computing a size scale factor denoted

defined by the function

fct_IDEl. The size

scaling factor evolution is given with respect to the ratio of initial

element characteristic length divided by a reference size

El_ref (by default = 1.0):

. An additional scale factor

Fscale_El can also be applied to the entire

regularization function. The element size scale factor

thus computed is introduced in the damage

variable evolution equation (and if defined, the instability variable

evolution equation) as:

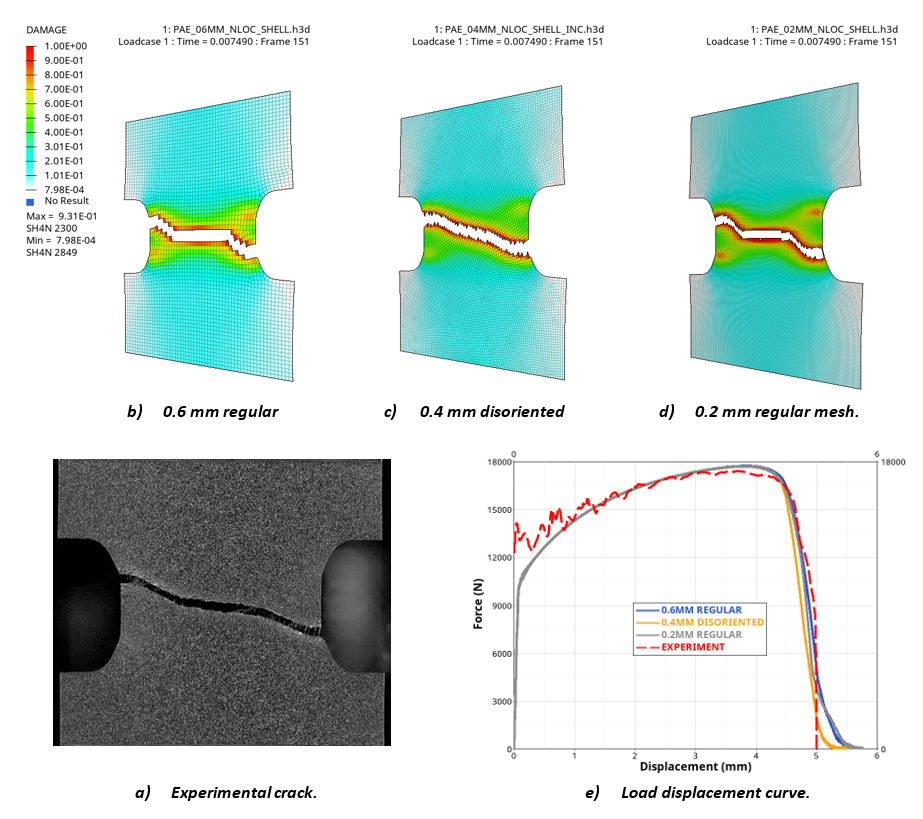

(13) - Alternatively, the /NONLOCAL/MAT option which is

compatible with Syazwan failure criterion (Figure 6) can be used to regularize the

solution according to mesh size and orientation. If the non-local

regularization is used, the non-local plastic strain is used to compute the

damage evolution (and the instability variable, if used). In that case, the

maximum non-local length parameter LE_MAX is used instead of the initial

element size if an element size scaling is defined through

fct_IDEl. Also, the

non-local regularization is also available with the “one-step” damage field

initialization.

Figure 6. Example of /NONLOCAL/MAT option cumulated with /FAIL/SYAZWAN on automotive DP450 steel